Search Result

Search ResultDeep decarbonisation of industry: The cement sector

Headlines Fossil fuel combustion to meet heating needs accounts for 35% of cement’s CO2 emissions. The remaining 65% are due to direct process emissions, which must also be addressed. The biomass use…

Read Full articleIndustrial Symbiosis And How To Engage Stakeholders

The following article is a summary of the report “Inventory of best practices from the CORALIS demonstrators" delivered by the EU project CORALIS. And it is also a training article for the Enerwhizz ,…

Read Full articleSignificant cost savings & lowered CO2 Emissions through efficient Heat-Recovery Solutions

Marc Delannoy, General Manager Airflux: “Airflux selected SWEP as a partner for two main reasons. First, SWEP is a well-known brand, appreciated in the heat exchange industry. Furthermore, one of our main partners was already successfully integrating SWEP's brazed plate heat exchangers in their systems. We have had a positive experience of integrating SWEP heat exchangers into our customers'…

Read Full Business PracticeSonac - heat recovery from high corrosive flue gas

Sonac uses, amongst others, animal fat residues to fire steam boilers. This examples describes how Sonac uses a HeatMatrix system to recover waste heat from the highly corrosive flue gas to heat up boiler feed water.

Read Full Business PracticeHeat Recovery from Biomass with ORC technology

From Biomass, Turboden provides solutions to produce heat and electrical power with high efficiency. Solution includes cogeneration plants with ORC which generate power usually ranging between 200 kW and 20 MW electric. By using wood and waste material as fuels, Turboden ORC solutions allow to provide heat for consumers from district heating, timber drying, wine industry, MDF/PB, sawdust drying...

Read Full Business PracticeEasy Read - ORC technology for waste heat recovery

In an easy-to-read paper, German company DeVeTec describes the ORC technology including various application areas based on different heat sources, e.g. exhaust gas, hot air or flue gas. A typical issue is covered as well - fluctuating heat volumes and temperatures.

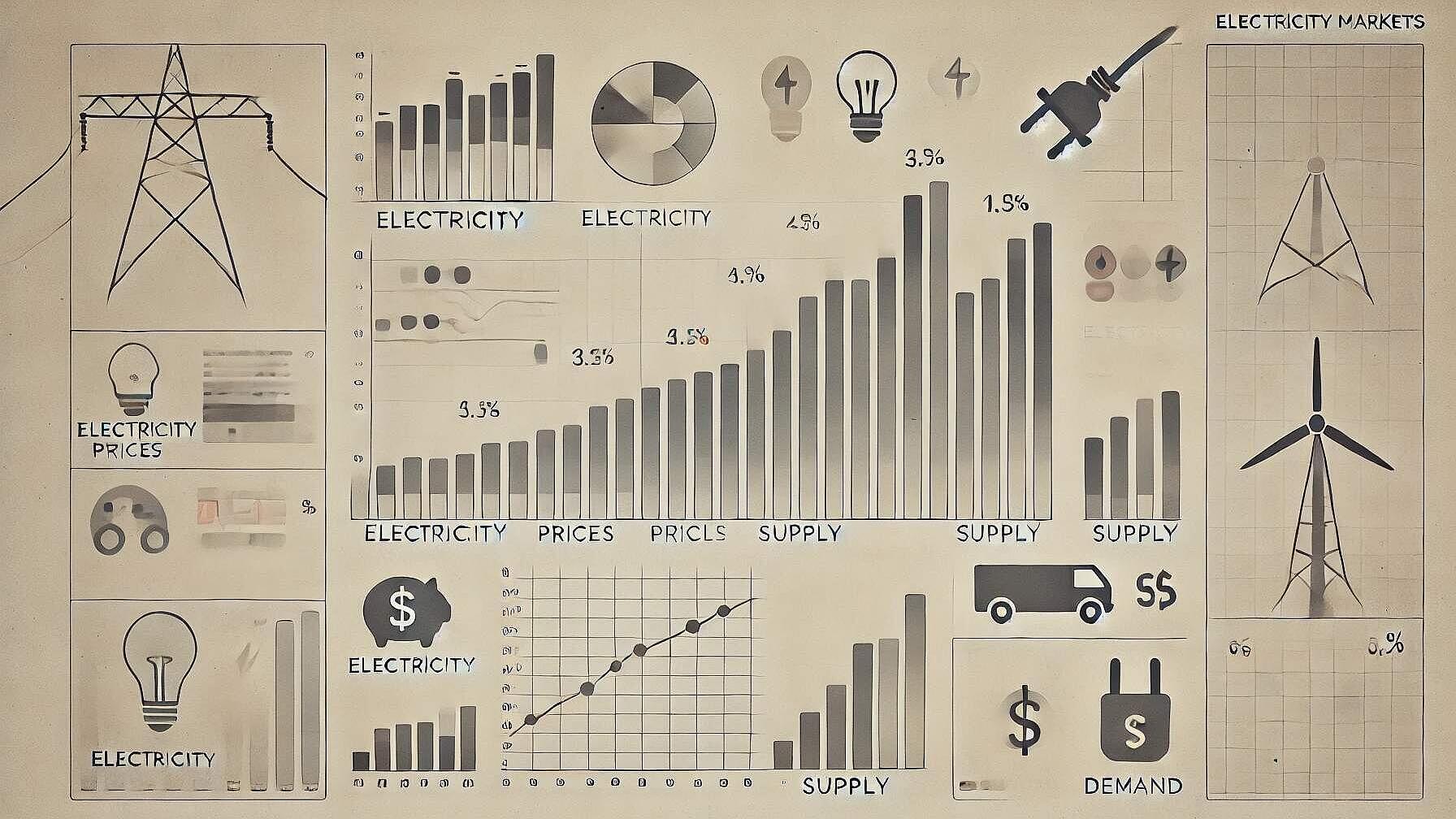

Read Full Business PracticePowering Ahead: The Global Electricity Landscape Through 2026

The global electricity sector stands at a pivotal juncture as it navigates the transition to cleaner energy sources while meeting rising demand. According to the International Energy Agency's latest…

Read Full articleHow Energy Efficiency and Renewables will benefit from COVID-19

Since 1900 only three events had a greater impact on global energy demand than COVID-19: The Spanish flu, the Great Depression and World War II. So now COVID-19. Can we already predict the near and/or…

Read Full articleBusiness Value Through Industrial Symbiosis

The following article is a summary of the report “A Business Value Framework for Industrial Symbiosis” delivered by the EU project CORALIS. And it is also a training article for the Enerwhizz , which…

Read Full articleORC Plants for Industrial Heat Recovery

ORC (organic ranking cycle) technology can be used to produce electricity by recovering heat from industrial processes, reciprocating engines and gas turbines. In this example, turbogenerators from Turboden are described, being able to generate power in ranges between 200 kW and 20 MW electric.

Read Full Business Practice