Energy Efficiency

Energy EfficiencyElectrifying Industry: The Path to Decarbonizing Process Heat

Summary

The Agora Industry study indicates that direct electrification could meet 90% of the unmet energy demand in European industry by 2035, significantly reducing CO2 emissions and advancing EU climate goals. Currently, industrial process heating, powered largely by fossil fuels, represents 47% of industrial energy use and the majority of the sector's CO2 emissions. Direct electrification, deploying technologies like electric boilers, heat pumps, resistance and induction heating, plasma torches, electric arc furnaces, and emerging innovations, could serve a range of temperatures needed for various processes.

The study explores sector-specific opportunities, highlighting potential in the iron and steel sector with electric arc furnaces and in the chemicals industry through electrified steam production. Further potential lies in non-ferrous metals, non-metallic minerals, food, beverages, tobacco, and the paper and pulp industries.

Barriers to adoption include technical challenges for specific high-temperature processes, economic hurdles due to electricity costs, and organizational barriers, such as inadequate electrical infrastructure.

Overcoming these barriers would necessitate a supportive economic framework involving carbon pricing, investments in infrastructure, technology development, early adoption encouragement, and addressing policy uncertainty.

While hydrogen is recognized as a valuable complement, the study emphasizes prioritizing direct electrification where feasible. Achieving significant decarbonization in European industry will require collaborative efforts from policymakers, industry leaders, and technologists.

Open full article

Electrifying Industry: The Path to Decarbonizing Process Heat

As the world races to decarbonize, industrial process heating emerges as a critical frontier. A study by Agora Industry reveals that direct electrification technologies could potentially meet 90% of the energy demand not yet electrified in European industry by 2035. This finding points to a transformative opportunity to slash carbon emissions, bolster competitiveness, and accelerate progress towards EU climate targets.

The Current Landscape

Today, process heating accounts for a staggering 47% of industrial energy demand and roughly three-quarters of the sector's CO2 emissions. Fossil fuels, particularly natural gas (35%) and coal (27%), dominate the energy mix for process heating. Electricity, at a mere 4%, plays a minimal role currently. This heavy reliance on fossil fuels presents both a challenge and an opportunity for decarbonization efforts.

The Promise of Direct Electrification

Direct electrification involves using electricity to generate heat immediately, without intermediate steps. The study identifies several key technologies that could drive this transition:

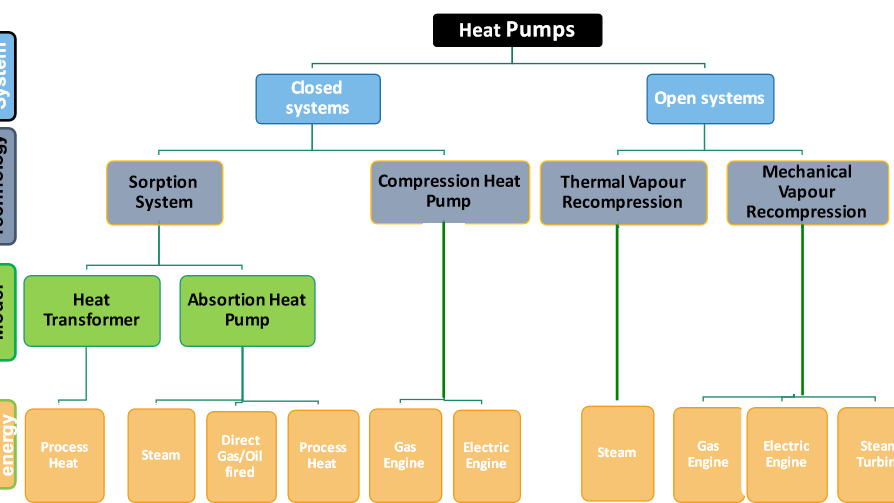

1. Electric boilers and heat pumps for low to medium temperatures

2. Resistance heating for a wide range of applications

3. Induction heating for metal processing

4. Plasma torches for high-temperature processes

5. Electric arc furnaces for steel production

6. Emerging technologies like shock-wave heating

These technologies collectively offer the potential to cover temperatures ranging from under 100°C to over 1500°C, addressing the diverse needs of various industrial processes.

Sector-Specific Opportunities

The study examines the electrification potential across major industrial sectors:

Iron and Steel: While challenges remain in primary steelmaking, electric arc furnaces for secondary steel production and the potential electrification of reheating processes offer significant opportunities.

Chemicals: Electrified steam cracking and steam production present substantial potential, with heat pumps offering considerable efficiency gains at suitable temperatures.

Non-Ferrous Metals: Already heavily electrified, the remaining fossil fuel use in this sector could be largely replaced by electric heating technologies.

Non-Metallic Minerals: High-temperature processes like cement clinker production pose challenges, but emerging technologies like plasma heating and shock-wave heating show promise.

Food, Beverages, and Tobacco: Low-temperature processes in this sector are highly suitable for electrification through heat pumps and electric boilers.

Paper and Pulp: Steam generation, a major energy consumer in this industry, can be effectively electrified using existing technologies.

Overcoming Barriers to Adoption

Despite the immense potential, several barriers currently hinder widespread adoption of direct electrification:

Technical Challenges: While many applications can already be electrified, some high-temperature, high-capacity processes still require further technological development.

Economic Hurdles: The current price differential between electricity and natural gas often makes electrification economically unattractive without additional incentives or carbon pricing.

Organizational Barriers: Insufficient electrical infrastructure, the need to modify existing production processes, and uncertainty about future energy prices and policies all contribute to hesitancy in adopting new technologies.

The Path Forward

To accelerate the transition to electrified process heating, the study suggests several key actions:

- Create a Supportive Economic Framework: Policies that make electricity more cost-competitive with natural gas, such as carbon pricing or targeted subsidies, are crucial.

- Invest in Infrastructure: Upgrading electrical grids and on-site connections is essential to support increased electricity demand.

- Support Technology Development: Continued research and development, especially for high-temperature applications, can help overcome remaining technical barriers.

- Encourage Early Adoption: Supporting pilot projects and partial electrification can facilitate learning and build confidence in new technologies.

- Address Uncertainty: Clear communication about future energy policies, hydrogen availability, and grid development can help businesses make informed investment decisions.

- Promote Knowledge Sharing: Increasing awareness of available and emerging electrification solutions across industries is vital.

The Role of Hydrogen

While direct electrification shows immense promise, the study acknowledges that hydrogen will likely play a complementary role in decarbonizing industry. Hydrogen may be particularly relevant for applications that are challenging to electrify directly, such as certain chemical processes or as a reducing agent in steelmaking. However, the study emphasizes that direct electrification often offers greater efficiency and should be prioritized where feasible.

Conclusion

The transition to electrified process heating represents a monumental opportunity for European industry to dramatically reduce its carbon footprint while potentially improving energy efficiency and competitiveness. With 62% of industrial fuel demand potentially replaceable by direct electrification using technologies available today, and further potential unlocked by 2035, the path to a decarbonized industrial sector is becoming increasingly clear.

However, realizing this potential will require concerted effort from policymakers, industry leaders, and technology developers. By addressing economic barriers, supporting infrastructure development, and fostering innovation, Europe can position itself at the forefront of the global transition to clean industry. As the world grapples with the urgent need to address climate change, electrifying industrial process heat emerges as a powerful and increasingly feasible solution to one of the most challenging aspects of decarbonization.