Renewable Energy

Renewable EnergyElectrifying the Future: Joule-Heated Catalytic Reactors as a Pathway to Decarbonization and Innovation

Summary

The paper discusses the potential of Joule-heated catalytic reactors to decarbonize energy-intensive chemical manufacturing. Traditional chemical processes rely heavily on fossil fuel combustion, contributing significantly to CO2 emissions. Electrification via Joule heating provides a cleaner alternative by using electrical resistance to generate heat, enabling integration with renewable energy and enhancing energy efficiency.

The review outlines how Joule heating offers fast, uniform heating and can retrofit into existing systems. Structured catalysts in such reactors improve energy transfer to catalytic sites, intensifying processes and reducing footprint. The technology shows particular promise in methane steam reforming and CO2 valorization, with lab-scale reactors achieving high energy efficiencies and enabling precise reaction control.

The EU’s STORMING project is mentioned as an example of integrating Joule heating into innovative reactor designs for methane conversion and material production. The wider impact of Joule heating includes opportunities for those in chemical engineering, energy, and policy, and its compatibility with the shifting energy landscape, particularly with the growth of renewables.

In conclusion, Joule-heated catalytic reactors offer a scalable pathway for the decarbonization of chemical processes, representing a significant advancement towards sustainable industry practices.

Open full article

Electrifying the Future: Joule-Heated Catalytic Reactors as a Pathway to Decarbonization and Innovation

In today's energy landscape, one of the most pressing challenges is reducing greenhouse gas emissions, particularly from energy-intensive industries like chemical manufacturing. With climate change growing more urgent, new approaches are being explored to replace traditional fossil fuel combustion, a significant source of CO2 emissions. One such innovation is the electrification of chemical processes, especially through **Joule-heated catalytic reactors**, which offer a cleaner, more efficient means of generating the heat needed for these energy-intensive reactions. The recently published review on "Joule-Heated Catalytic Reactors Toward Decarbonization and Process Intensification" provides a comprehensive overview of this promising technology, with implications for the broader energy transition.

A New Era of Process Electrification

The chemical industry is one of the largest consumers of energy, responsible for vast amounts of CO2 emissions. For example, ammonia production alone, a critical process in chemical industries, is responsible for the release of 550 million tons of CO2 annually. In 2015, the chemical industry consumed about 43 exajoules of energy, contributing 3.3 gigatons of CO2 to the atmosphere. A significant share of this energy is used to provide heat for endothermic chemical reactions, which have traditionally relied on fossil fuel combustion. To tackle this, electrification of these processes, particularly via Joule heating, emerges as a viable solution for decarbonizing industrial activities.

**Joule heating**—also known as resistive or ohmic heating—is an electrical process where heat is generated by passing an electric current through a conductor. This method offers several advantages over conventional heating techniques, such as fast and uniform heating, improved energy efficiency, and the ability to integrate with renewable electricity sources like wind and solar power. In this review, the authors highlight Joule heating as a particularly promising method for methane reforming, cracking reactions, and CO2 valorization.

Innovations Driving the Change

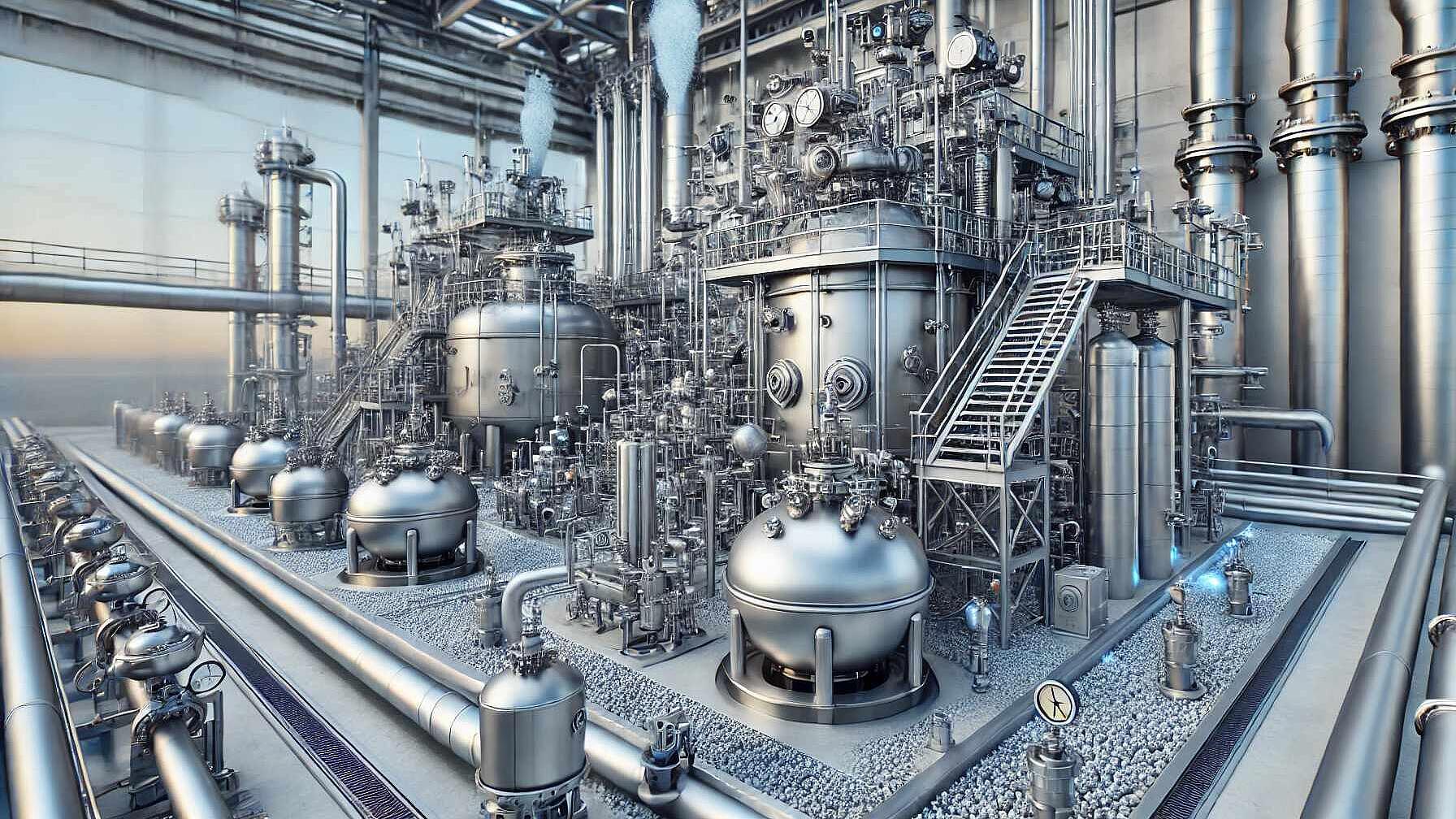

Joule-heated catalytic reactors stand out not only because they replace fossil fuel-based heat sources but also because they promise significant gains in process efficiency and reactor design flexibility. Unlike traditional reactors where heat is applied externally, **Joule-heated reactors** can directly target the catalytic elements, reducing energy losses and improving heat transfer. This creates opportunities for process intensification, allowing for more compact reactor designs and minimizing inefficiencies caused by heat transfer limitations.

A key innovation in this area is the integration of **structured catalysts** with Joule-heated reactors. Structured catalysts, such as washcoated foams and monoliths, have high thermal conductivity and can be directly heated, ensuring that heat is transferred efficiently to the active catalytic sites. This is crucial for reactions like methane reforming, where maintaining high temperatures is essential for maximizing hydrogen production. In comparison to other electrification methods, such as microwave or induction heating, Joule heating is more straightforward and can be retrofitted into existing systems with relative ease, making it a more viable near-term solution for industries seeking to decarbonize.

Real-World Applications and Case Studies

One of the most promising applications of Joule heating is in **methane steam reforming (MSR)**, a process widely used for hydrogen production. Traditionally, MSR relies on burning methane to generate the heat necessary for the endothermic reactions. However, this approach produces significant amounts of CO2. By replacing combustion with Joule heating, it is possible to drastically reduce these emissions. For example, recent studies have demonstrated that Joule-heated reactors can achieve energy efficiencies of over 80% in lab-scale setups. Moreover, Joule-heated reactors enable process intensification, allowing for higher throughput with a smaller reactor footprint, making them ideal for decentralized hydrogen production.

Another area where Joule-heated reactors show great promise is in **CO2 valorization**. CO2 can be converted into valuable chemicals and fuels through processes like dry reforming of methane or the reverse water-gas shift reaction. These reactions are endothermic and require significant heat input, traditionally provided by burning additional fossil fuels. Electrifying these processes with Joule-heated reactors not only eliminates the need for fossil fuel combustion but also allows for more precise control over reaction conditions, improving efficiency and selectivity.

Moreover, the **EU's STORMING project** is exploring innovative reactor designs that integrate Joule heating for methane conversion, producing not only hydrogen but also high-value carbon nanomaterials. This project exemplifies the dual benefit of electrified reactors, which not only reduce CO2 emissions but also contribute to the development of advanced materials for future energy applications, such as batteries.

Impact on the Future of Energy and Industry

The potential impact of Joule-heated catalytic reactors on the energy sector is profound. As industries transition to greener technologies, electrification of chemical processes could play a critical role in decarbonizing sectors that are traditionally hard to abate. For students and young professionals entering fields like chemical engineering, energy, and environmental policy, these developments open up exciting new career opportunities. Whether it’s through research, entrepreneurship, or policy advocacy, the need for expertise in electrified processes will only grow as the world shifts toward a more sustainable energy future.

**Joule heating** also aligns with broader trends in the energy sector, such as the increasing availability of **renewable electricity**. As solar and wind power continue to expand, the intermittency of these energy sources presents challenges for maintaining a stable energy supply. Joule-heated reactors offer a solution to this problem. By integrating with smart grid technologies, these reactors can operate dynamically, adjusting their energy consumption based on the availability of renewable power. This flexibility makes them an ideal complement to the evolving energy grid, where balancing supply and demand is increasingly critical.

A Call to Action for Future Innovators

As we look to the future, it’s clear that **Joule-heated catalytic reactors** have the potential to revolutionize the chemical industry. By providing a clean, efficient alternative to fossil fuel combustion, they offer a pathway to decarbonization that is both practical and scalable. For young professionals, now is the time to get involved in this burgeoning field. Whether through education, hands-on research, or participation in forward-thinking projects like STORMING, there are countless opportunities to contribute to the future of clean energy.

In conclusion, the future of the chemical industry is electric, and **Joule-heated catalytic reactors** are at the forefront of this transformation. By harnessing the power of renewable electricity, these reactors not only reduce CO2 emissions but also offer new possibilities for process innovation and sustainability. As industries across the globe strive to meet their decarbonization goals, Joule heating represents a vital tool in the journey toward a cleaner, more sustainable world.