Renewable Energy

Renewable EnergyInnovative Pathways in Hydrogen Production: A Catalyst for Change in Clean Energy

Summary

The paper discusses the shift toward cleaner energy with hydrogen as a key clean energy component. Hydrogen's current annual production is significant, but the prevalent production method, steam methane reforming (SMR), emits large amounts of CO2. Catalytic methane decomposition (CMD) is presented as a cleaner alternative, producing hydrogen and solid carbon without direct CO2 emissions, requiring less energy than SMR and circumventing certain environmental costs.

The paper identifies iron (Fe)-based catalysts as promising for CMD due to their efficiency and cost-effectiveness. These catalysts work at higher temperatures and have been particularly effective when fused with alumina (Fe-Al2O3), exhibiting increased performance and longevity. This approach not only yields hydrogen but also valuable carbon nanomaterials that have applications in advanced battery technologies.

The European Union's STORMING project illustrates how combining hydrogen production with materials science can create integrated energy solutions. These technological advancements could have a wider impact on energy storage, electronics, and provide new job opportunities in energy and materials science sectors.

The paper suggests that CMD's environmental benefits are significant, reducing greenhouse gases and contributing to a circular economy. It invites students and young professionals to get involved in hydrogen technology and CMD through education and participation in research projects. Entrepreneurial prospects in commercializing carbon nanomaterials are discussed, pointing to clean energy as a realm of vast potential for the future.

Open full article

Innovative Pathways in Hydrogen Production: A Catalyst for Change in Clean Energy

Current Landscape

The global shift towards cleaner energy sources is no longer a distant ideal but a pressing reality. Hydrogen, recognized as a pivotal component in the clean energy transition, holds immense potential. The annual production of hydrogen is estimated at around 0.1 gigatons, yet the dominant production method—steam methane reforming (SMR)—comes with a hefty environmental price, emitting roughly 500 million tons of CO2 annually. As a result, the energy sector is increasingly exploring cleaner alternatives like catalytic methane decomposition (CMD).

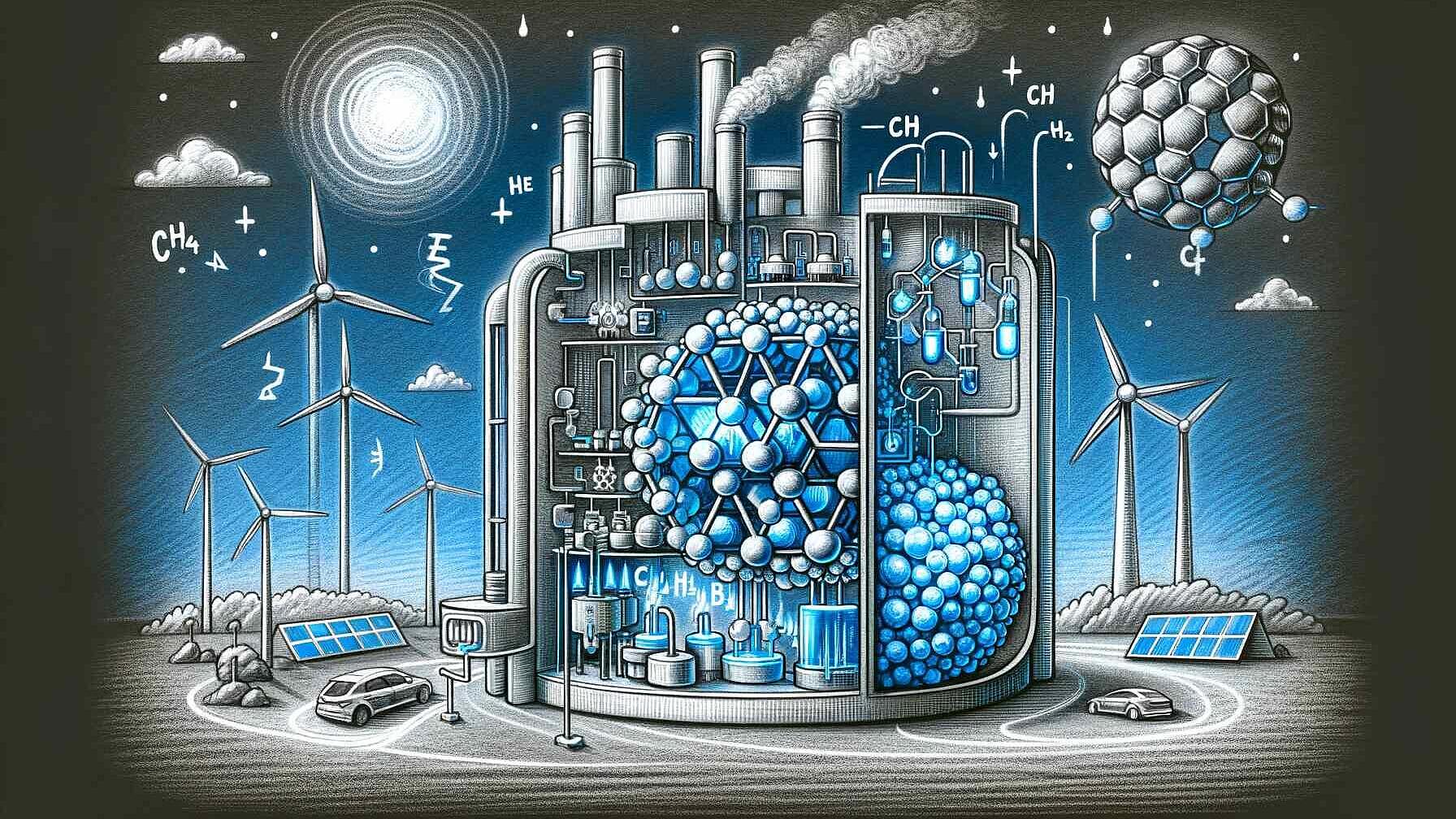

Unlike SMR, CMD produces hydrogen without direct CO2 emissions. This method breaks down methane (CH4) into hydrogen (H2) and solid carbon, a much greener alternative. While steam reforming is highly industrialized, CMD is still developing but offers significant environmental advantages. Studies have shown that CMD requires significantly less energy per mole of hydrogen compared to SMR (37.8 kJ/mol versus 63.3 kJ/mol, respectively).

Ni-based catalysts are the most studied for CMD, yet they come with several challenges, particularly deactivation due to carbon deposition. This highlights the need for more cost-effective, robust alternatives, such as iron (Fe) catalysts, which show promising results in hydrogen production.

Innovations and Opportunities

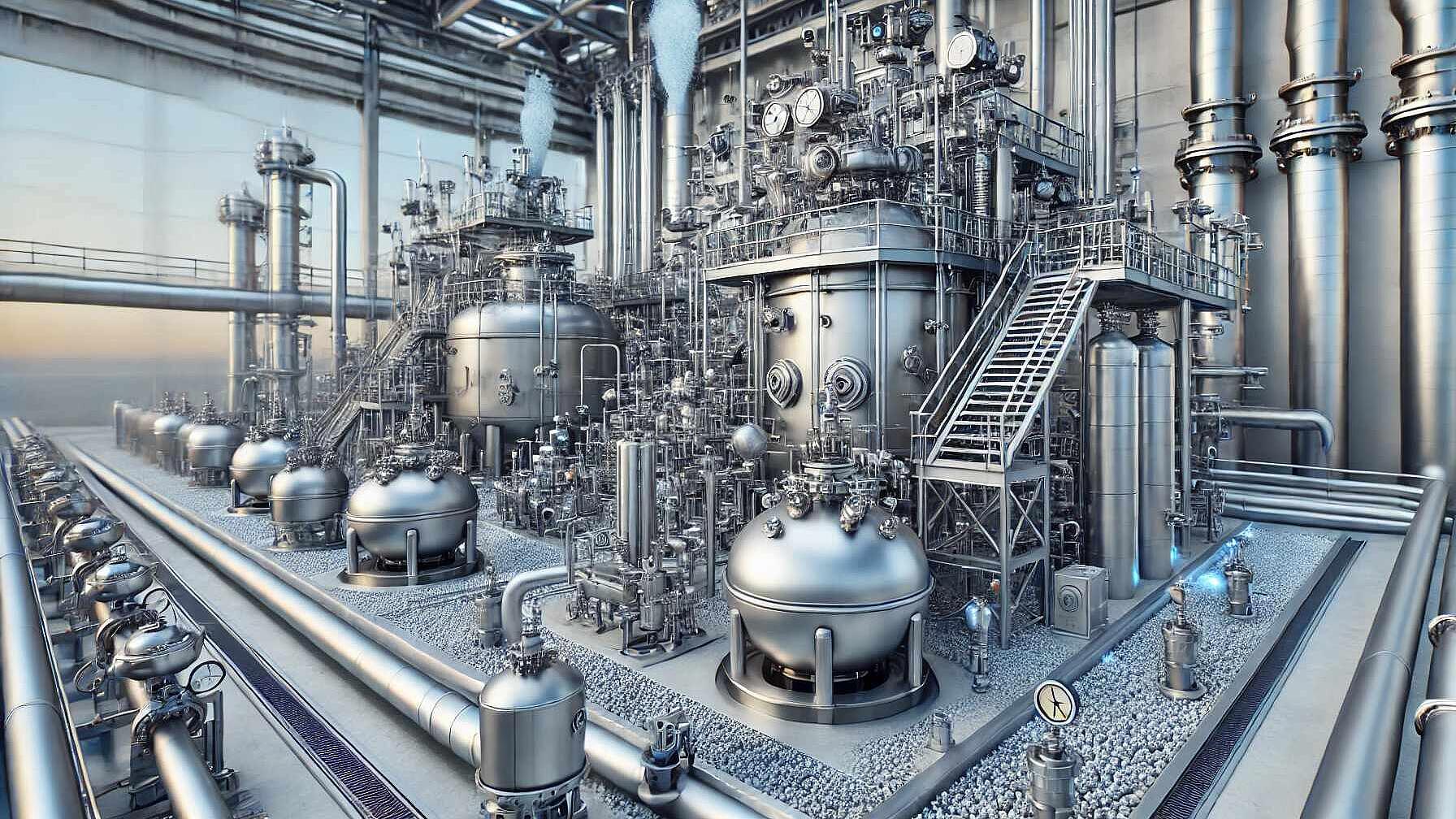

Researchers have identified Fe-based catalysts as a key innovation in CMD due to their abundance and cost-effectiveness compared to nickel-based alternatives. These catalysts operate at higher temperatures (700–950°C), enhancing their thermodynamic conversion efficiency. A notable breakthrough in this area is the development of fused Fe-Al2O3 catalysts, which offer optimal performance for methane decomposition, producing both hydrogen and valuable carbon nanomaterials.

One of the most exciting opportunities is how these carbon nanomaterials, a byproduct of CMD, can be repurposed for advanced applications such as battery technologies. The European Union’s STORMING project is a prime example of how integrated technologies can simultaneously address energy production and materials science. STORMING develops reactors that convert methane into hydrogen and carbon nanomaterials without producing CO2, using structured reactors heated by renewable electricity.

Fused Fe-Al2O3 catalysts, in particular, have shown superior performance compared to other catalysts. The combination of iron with alumina (Al2O3) helps expose more active Fe sites, enhancing methane decomposition efficiency. These catalysts are also more resistant to deactivation, thanks to the formation of carbon nanotubes (CNTs) rather than carbon nano-onions (CNOs), which trap the Fe catalyst particles. This ensures a longer catalyst life, making the process more economically viable.

Impact

The potential impact of these innovations extends far beyond hydrogen production. The creation of carbon nanomaterials, such as CNTs, offers substantial opportunities in fields like energy storage and electronics. As hydrogen becomes an increasingly integral part of the energy landscape, the demand for skilled professionals in energy, materials science, and industrial applications will grow. Young innovators and professionals in these sectors will find themselves at the forefront of this transition, whether through academic research, entrepreneurial ventures, or contributions to large-scale projects like STORMING.

Beyond career opportunities, CMD's environmental impact cannot be overstated. The process not only reduces greenhouse gas emissions but also contributes to the circular economy by turning methane—a greenhouse gas—into valuable products. For students and young professionals looking to make a tangible impact in the fight against climate change, CMD presents a promising avenue for exploration.

Call to Action

For those inspired by the possibilities of hydrogen technology and CMD, there are several ways to get involved. Universities, research institutions, and EU-funded projects like STORMING provide numerous opportunities for further education and hands-on experience. Engaging with industry developments, staying informed about technological advances, and participating in research initiatives can help build the skills needed to contribute to this growing field.

Moreover, those with an entrepreneurial spirit can explore how carbon nanomaterials can be commercialized in various sectors, from renewable energy to electronics. As clean energy becomes a global priority, the potential for CMD and related technologies to shape the future is vast.

Conclusion

Hydrogen production through CMD represents a significant leap toward a cleaner, more sustainable future. By harnessing the power of innovative catalysts like Fe-Al2O3 and leveraging the potential of carbon nanomaterials, the energy sector is poised for transformative change. For students and young professionals entering the field, this is an exciting time to be involved in the development of breakthrough technologies that will drive the clean energy revolution. As projects like STORMING demonstrate, the integration of renewable energy with industrial processes can lead to a more sustainable, CO2-free future.

Now is the time to engage with these innovations and contribute to the next generation of energy solutions. Whether through research, industry involvement, or entrepreneurial ventures, the future of hydrogen and clean energy is full of opportunities waiting to be explored.