Energy Efficiency

Energy EfficiencyWater & energy reuse: from waste to resource

Summary

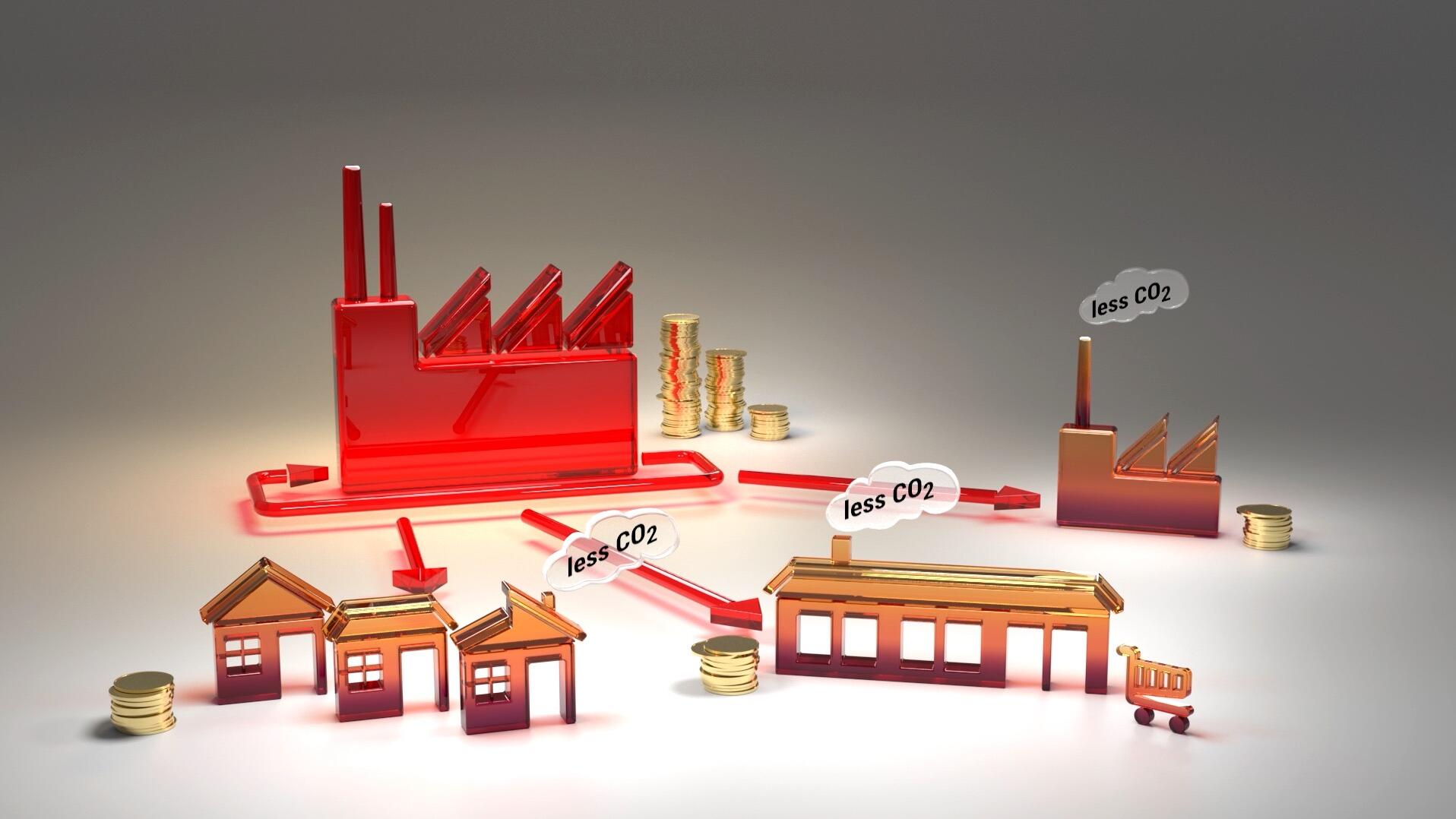

Over recent years, the EU has emphasized collaboration between industries and academia to create eco-friendly and profitable products, focusing on transforming industrial waste into valuable resources. Alufluor, a Swedish chemical company, produces aluminium fluoride and has partnered with the EU-funded iWAYS project to address its environmental challenges. The iWAYS initiative aims to reduce emissions, recycle materials, heat, and water. Through this collaboration, Alufluor intends to conserve about one-third of its water waste and decrease its biogas usage by 20%. The core technology introduced by iWAYS, the heat pipe condensing economiser (HPCE), facilitates heat, water, and material recovery. Alufluor is also implementing an integrated water treatment system to save approximately 60,000 m3/year of drinking water. The iWAYS project's innovations benefit various industries, ensuring sustainability without compromising economic growth.

Open full article

Water & energy reuse: from waste to resource

Francesco Suman explains how Alufluor found novel ways to recover resources by partnering with an EU-funded project.

Over the past years, EU industries and academics have increasingly collaborated to develop environmentally friendly yet profitable products. The focus of research is increasingly shifting towards converting industrial waste into economically valuable resources, especially with raw materials and by-products from industries that operate at high temperatures, like chemicals.

An interesting example of this approach is found in Alufluor, a chemical company based in Helsingborg, Sweden. Alufluor produces aluminium fluoride, a crucial ingredient in the aluminium melting process. The company is quite well known in the industry for its compound production, especially given its purity rate of 97.5%.

The production process generates a lot of wastewater, gases and chemical compounds that must be treated or removed. For example, drying generates hot vapours containing residual materials. Although these gases are filtered and scrubbed before flowing into the chimney, some waste still manages to escape.

Moreover, the process requires hot water to clean the reactors, wash the centrifuges and minimise any loss of fluorides in the process. Energy consumption is another critical issue: the whole industrial process requires a fair amount of power, mainly for drying aluminium fluoride and heating water.

Alufluor already recycles part of its heat, but the demand continues to be high. As a result, the company relies on a biogas-driven steam generator, representing one of its highest energy costs. As a result, it was one of 19 companies that took part in the iWAYS project, a research initiative funded by the European Commission.

In iWAYS, universities and companies collaborate to develop techniques for reducing emissions and recycling materials, heat and water. Some of these technologies will allow Alufluor to save and reuse approximately one third of the water it usually produces as waste and reduce its biogas consumption by one-fifth.

“iWAYS not only allows us to be more efficient and lower production costs, but it also gives us further strength in our sustainability brand,” says Dan Turesson, a mechanical engineer who is the technical director at Alufluor.

Saving energy & reducing emissions

The heat pipe condensing economiser (HPCE) is the core technology developed by iWAYS scientists: it allows recovery of heat, water and materials. In addition, it is flexible enough to be adjusted to several industrial contexts.

The design was first developed by Professor Hussam Jouhara of Brunel University London. The University of Modena and Reggio Emilia worked on modelling, and EconoTherm, a UK company, manufactured the actual system.

Alufluor is about to install a multi-section iWAYS HPCE, expecting to increase energy recovery and reduce chimney emissions. “The condensation energy is much higher than the one you get from ordinary sensible heat exchangers,” says Turesson.

“Energy savings could double using iWAYS components. Consequently, we expect to reduce the need for steam used for heating washing water to a minimum. Of course, steam generators will remain as back-ups, but we can reduce biogas consumption by 20% with these innovations.”

Emission reduction will be achieved by burning less fuel and sending cleaner gases to the chimneys. This is because condensation takes up a lot of fluoride particles, acting as a scrubber. While some HPCE components are being manufactured, Alufluor is already experimenting with another essential part of the iWAYS project: the water-saving system.

Economic model based on water reuse

Today’s scrubber systems, which filter exhaust gases, use 8 m3/hour of drinking water to remove fluorides and other particles. In Alufluor’s case, this fluoridated water undergoes another process before being released into the sewer system.

This is not done just for environmental reasons but also to create a product that will be sold later.” Part of our sustainability also comes from the fact that we don’t have any solid waste, which normally every competitor has,” says Turesson.

Lime, rich in calcium, is added to the wastewater where fluorides are still floating. Calcium reacts with fluorides, forming calcium fluoride, which in turn is sold to the cement industry. Once again, the circular approach benefits the environment and business simultaneously. The rest of the water is then further purified and released into the sea, close to the Alufluor plant.

Calcium fluoride is sticky and there is always a small excess of calcium in the water – even tap water contains small amounts of it. Thus water needs to be purified before being reused in the scrubbers. Otherwise, the fluorides would bond with calcium, generating flaky particles that would inhibit functioning.

As part of its partnership with iWAYS, Alufluor is now installing an integrated water treatment system, allowing purified water into the scrubbers. The plan is to have two sand filters and two ionic filters, or softeners, which remove calcium from the water by adding sodium chloride. The water will then be sent to a tank and reused for the scrubbers.

Alufluor expects to save about 60,000 m3/year of potable water in this way. Another Italian company that is also an iWAYS participant, SINAM, produces both the sand filters and the ionic filters. It has already run a small pilot with these for more than one month without any issues.

“We still have a lot of water coming from the first reaction with the two raw materials, but we cannot do much with that at the moment,” says Turesson. “Nevertheless, saving and reusing the water for the scrubbers might be a first step: using the iWAYS technique could help save even more water during the whole process. We plan to make many changes to how we manage the washing water and how much energy we use for it.”

What scientists working at iWAYS have done for Alufluor has also been done for ceramic and steel tube companies, all industries that consume fuels and emit exhaust flow and wastewater – some more than others. Therefore, through such collaborations, European enterprises may remain sustainable in the long run without sacrificing economic growth.