Search Result

Search ResultSignificant cost savings & lowered CO2 Emissions through efficient Heat-Recovery Solutions

Marc Delannoy, General Manager Airflux: “Airflux selected SWEP as a partner for two main reasons. First, SWEP is a well-known brand, appreciated in the heat exchange industry. Furthermore, one of our main partners was already successfully integrating SWEP's brazed plate heat exchangers in their systems. We have had a positive experience of integrating SWEP heat exchangers into our customers'…

Read Full Business PracticeSWEP International

Challenge Efficiency: At SWEP, we believe our future rests on giving more energy than we take – from our planet and our people. That’s why we pour our energy into leading the conversion to sustainable energy usage in heat transfer. Over three decades, the SWEP brand has become synonymous with challenging efficiency. SWEP is a…

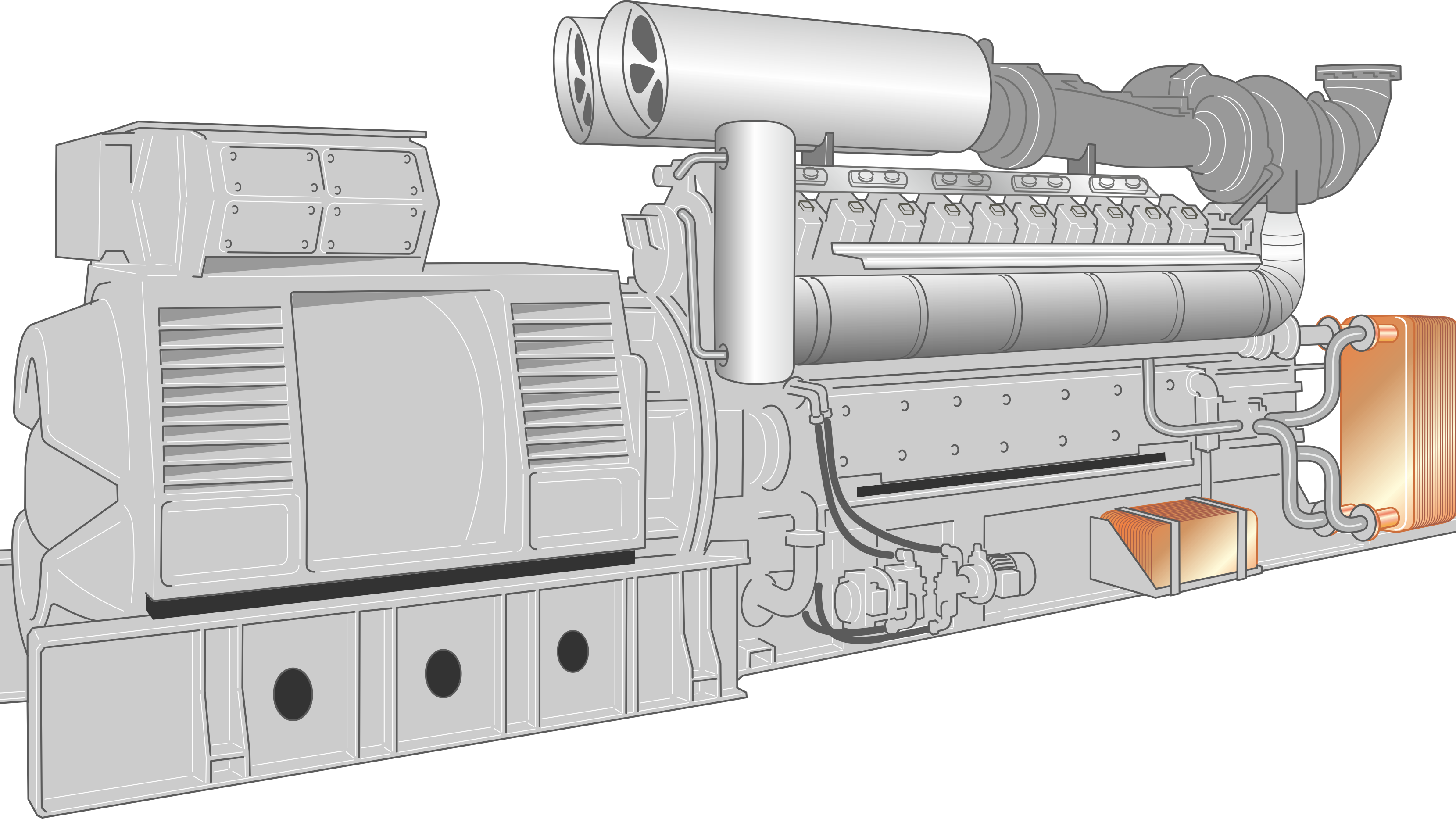

Rank Organic Rankine Cycle Technology with applications in Heat Recovery solution

In a project involving ACCIONA and KEROS CERAMICA, RANK has worked with SWEP to implement a heat recovery solution for electricity power generation. ORC RANK equipment capacities range from 2 to 100 kWe. The activation range for the low-temperature equipment starts at just 85 °C.SWEP's heat exchangers are installed as economizers, evaporators and condensers.

Read Full Business PracticeUtilize all the available energy — Heat recovery

Today, global industry consumes a vast amount of energy. The biggest challenge is that as much as half of it is wasted due to the inefficient and complicated recovery of low-grade energy. Heat in the…

Read Full articleORC-systems are helping to create a sustainable energy future

ORC (Organic Rankine Cycle) technology made possible by SWEP brazed plate heat exchangers is being used in Sweden to transform waste heat into renewable electricity. This high efficiency and low maintenance way to produce sustainable electricity is being adopted by district heating systems around the world. Read how Ronneby Municipality put this innovative technology to use.

Read Full Business PracticeOutokumpu Cools Machine Shop using natural Elements

To cool the rolling mill's machine shop, Outokumpu has chosen a solution that saves energy compared with more conventional alternatives. There are two ways to cool the machine shop. One is to use outdoor air, the other to use industrial water from a nearby river and cool the air through existing cooling coils and a SWEP B649 brazed plate heat exchanger.

Read Full Business Practice