Search Result

Search ResultHaving ‘Impossible’ conversations about energy

In my recent blogs on the future of energy I have had some really interesting debate on what will and won’t work… I’ve been challenged to consider Ammonia for air travel, a full Hydrogen switch over…

Read Full articleIoT READY - Noise and Vibration System in waste heat recovery application

Just two pages describing a Noise and Vibration Guard system for an ORC waste heat recovery application of DeVeTec. It links to a recently published EEIP post on IoT is Today. We called it IoT READY as it shows the emerging remote control options in industrial processes.

Read Full Business PracticeCase study cement industry: increased fuel efficiency

This short case study shows how data mining has led to significant and recurrent savings in a cement plant located in Belgium. In this example, the fueling of the multi-step-heating process of production lines was analyzed and optimized. A good case to show that data analytics might be capable to deliver the next step in energy efficiency.

Read Full Business PracticeThe Pitfalls of LED Linear Tubes and Smart Lighting Systems

from Wesley Whited, DNV GL The Pitfalls of LED Linear Tubes and Smart Lighting Systems At first glance, retrofitting an existing fluorescent fixture with an LED Linear tube seems like an appealing…

Read Full articleCompressed Air: Energy efficiency at the top of the ComVac agenda (HM17)

The latest edition of ComVac will soon be staged: from 24 to 28 April 2017 in Hannover, Germany, under the umbrella of HANNOVER MESSE. All up, some 260 exhibitors will be there in halls 26 and 27 to…

Read Full articleShining a light on Tomatoes

Royal Pride Holland is using the J624 GS engines to power the greenhouse's new cogeneration plant. Some of the power generated is used for lighting for the tomatoes, but most is supplied to the public power grid. Because the waste heat from the engines can be used at very low temperatures, and the CO2 in its exhaust gas can also be used, the overall level of efficiency is 95 percent.

Read Full Business PracticeOutokumpu Cools Machine Shop using natural Elements

To cool the rolling mill's machine shop, Outokumpu has chosen a solution that saves energy compared with more conventional alternatives. There are two ways to cool the machine shop. One is to use outdoor air, the other to use industrial water from a nearby river and cool the air through existing cooling coils and a SWEP B649 brazed plate heat exchanger.

Read Full Business PracticeBakery UK - production air with heat recovery

Just three months after installing two fixed-speed L110s and one regulated-speed L132RS compressor, along with a heat recovery system from CompAir, a leading supplier of bread products is on target to achieve annual energy savings in the region of £188,000, with a payback on investment in less than two years.

Read Full Business PracticeStart-up BATINEW: concept for a neighbourhood infrastructure

Short description of start-up BATINEW concept for a neighbourhood infrastructure which functions in symbiosis with different technologies and takes advantage of all available resources (solar power, organic waste, waste heat, waste water, etc.). Find out more about their innovative upcoming projects at the world’s leading trade fair Hannover Messe 2016. Visit Batinew at hall 2, stand C39

Read Full Business PracticeORC Technology in Waste to Energy Solutions

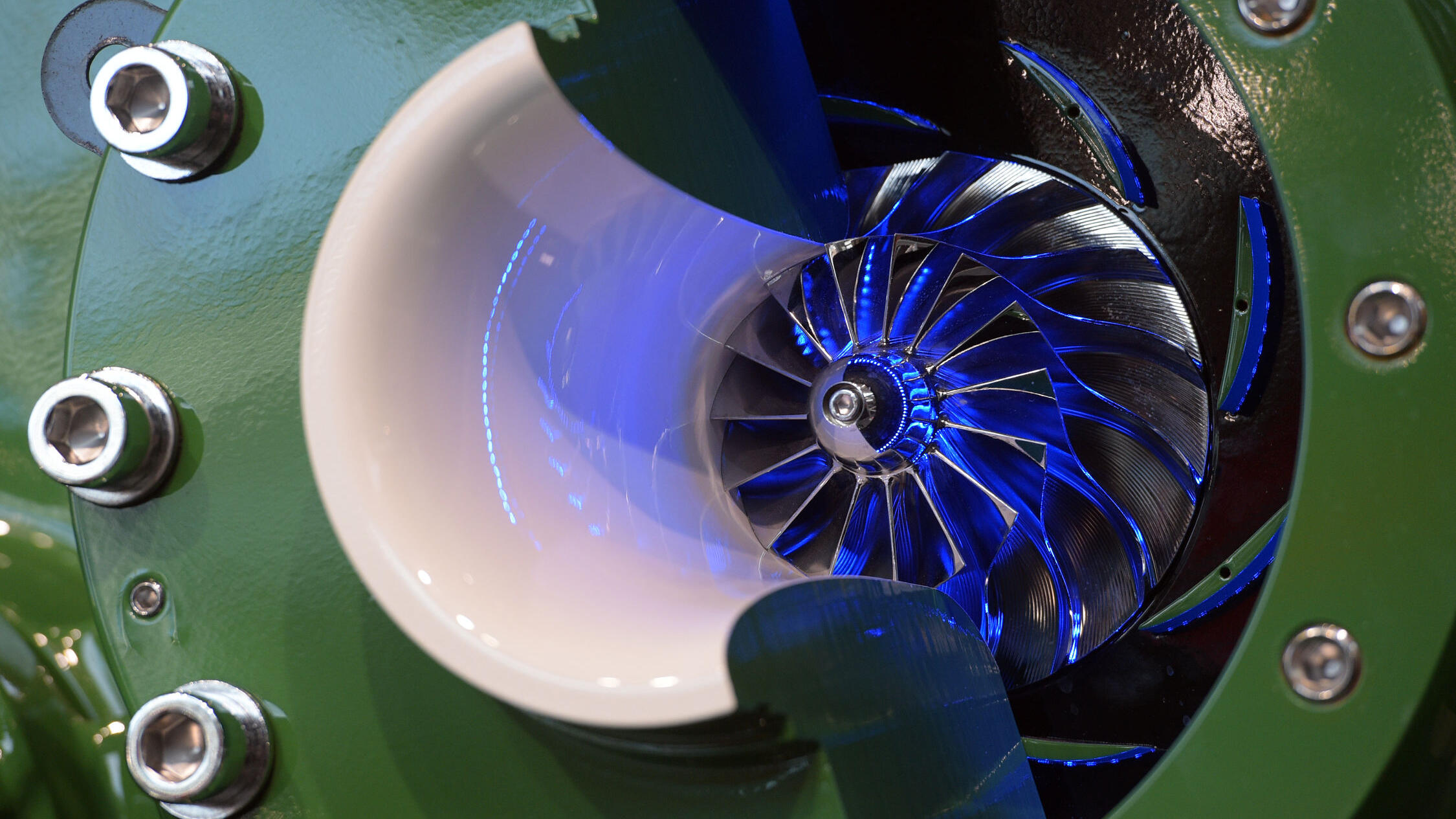

Turboden shows its ORC technology which can be profitably and efficiently used to produce electric using energy from waste to energy recovery processes which include steam or water from incinerator boiler, municipal solid waste gasification, landfill engines exhaust gas, primary heat conversion system. The power of Turboden turbogenerators in this application ranges from 200 kW to 20 MW electric.

Read Full Business Practice