Search Result

Search ResultBakery UK - production air with heat recovery

Just three months after installing two fixed-speed L110s and one regulated-speed L132RS compressor, along with a heat recovery system from CompAir, a leading supplier of bread products is on target to achieve annual energy savings in the region of £188,000, with a payback on investment in less than two years.

Read Full Business PracticeORC Technology in Waste to Energy Solutions

Turboden shows its ORC technology which can be profitably and efficiently used to produce electric using energy from waste to energy recovery processes which include steam or water from incinerator boiler, municipal solid waste gasification, landfill engines exhaust gas, primary heat conversion system. The power of Turboden turbogenerators in this application ranges from 200 kW to 20 MW electric.

Read Full Business PracticeORC Technology in Solar Thermal Power Plant

Turboden describes units allowing to convert heat collected by solar collectors into electricity through an efficient thermodynamic cycle. Concentrating Solar Power systems with Turboden ORC can be cost-effective in the range between 200 kW and 20 MW electric.

Read Full Business PracticeSalzgitter - pumps for district heating

Short description of how Salzgitter Flachstahl GmbH saved 53% of energy costs in their district heating operations. This has been achieved by a replacement of pumps with a new demand based pump control system.

Read Full Business PracticeInnovative system recovers heat, water and material from industrial waste streams

We are excited to announce that the first innovative Heat Pipe Condensing Economiser (HPCE) has been commissioned at our project partner Alufluor AB in Sweden and is running. The aluminium fluoride…

Read Full articleIoT READY - Noise and Vibration System in waste heat recovery application

Just two pages describing a Noise and Vibration Guard system for an ORC waste heat recovery application of DeVeTec. It links to a recently published EEIP post on IoT is Today. We called it IoT READY as it shows the emerging remote control options in industrial processes.

Read Full Business PracticeClean Power when ORC System recovers Waste Heat

Generating clean power in Japanese incineration plant: When the Japanese-based company Daiichi Jitsugy got a request from Ertec to install an ORC system in their new waste incineration plant, the company’s engineers knew that they would need a heat exchanger out of the ordinary.

Read Full Business PracticeElectrifying the Future: Joule-Heated Catalytic Reactors as a Pathway to Decarbonization and Innovation

In today's energy landscape, one of the most pressing challenges is reducing greenhouse gas emissions, particularly from energy-intensive industries like chemical manufacturing. With climate change…

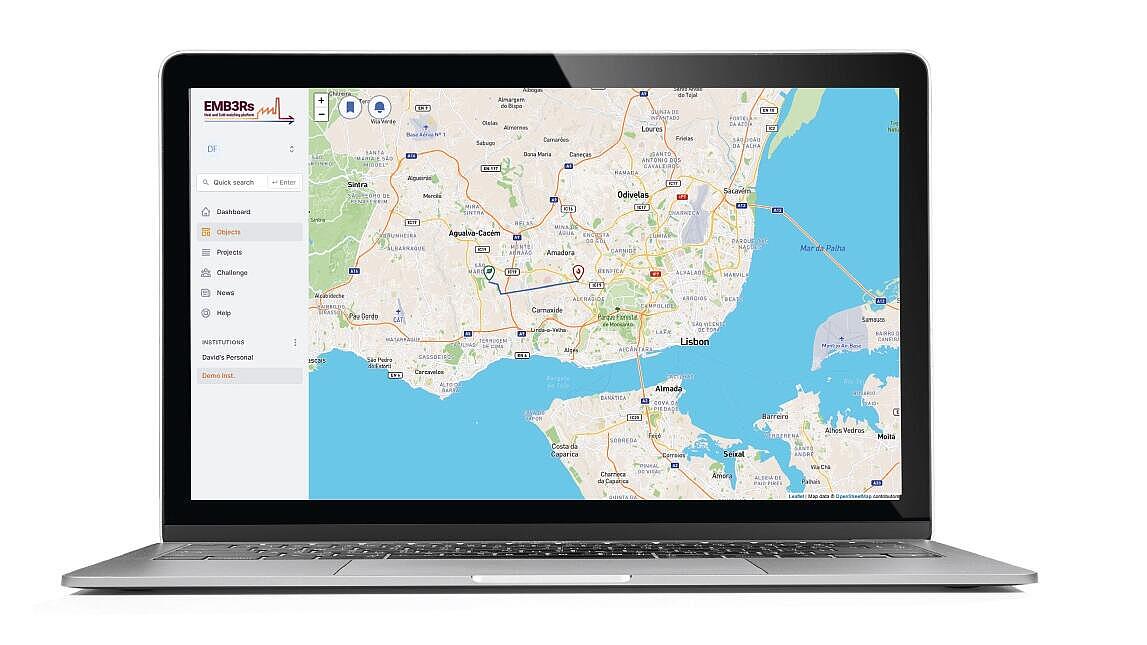

Read Full articleAn Uber for heat: How a new platform can help industries reuse excess heat and meet decarbonisation goals

Mafalda Silva is a Senior Researcher at the Institute of Science and Innovation in Mechanical and Industrial Engineering ( INEGI ) at the University of Porto. She has a PhD in Sustainable Energy…

Read Full articleBioenergy and Solid Biomass: A Renewable Solution for Industrial Heat Processes

Bioenergy, derived from solid biomass, represents a significant portion of the European renewable energy mix. Accounting for around 60% of the total, it plays a crucial role in the production of…

Read Full article