Search Result

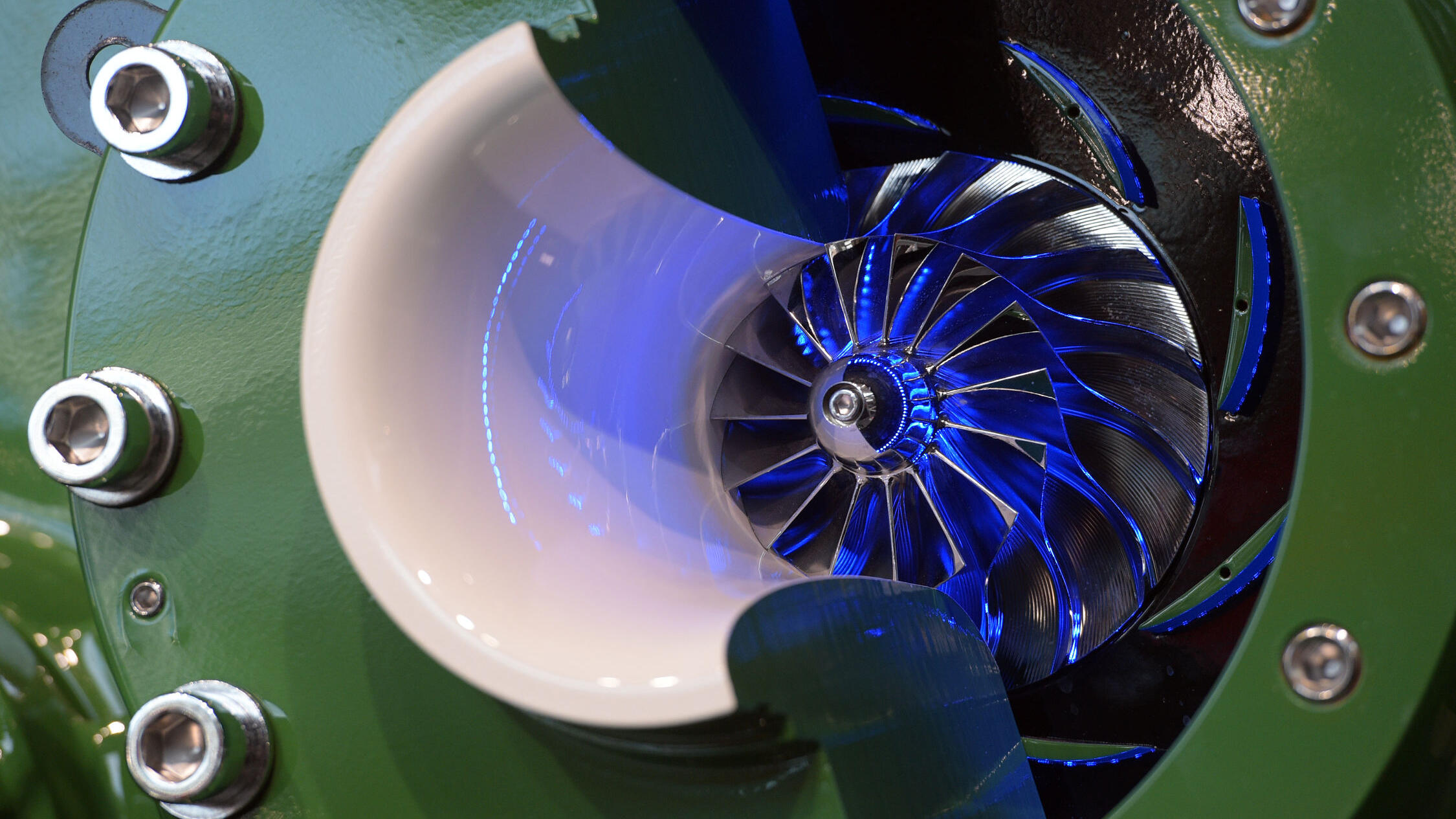

Search ResultORC Plants for Industrial Heat Recovery

ORC (organic ranking cycle) technology can be used to produce electricity by recovering heat from industrial processes, reciprocating engines and gas turbines. In this example, turbogenerators from Turboden are described, being able to generate power in ranges between 200 kW and 20 MW electric.

Read Full Business PracticeNext steps in financing energy efficiency improvements in Europe’s industry and energy supply

In the news: Training to be credentialed as a project developer for industrial energy efficiency and energy supply under the Investor Confidence Project will be held on September 11th. For more…

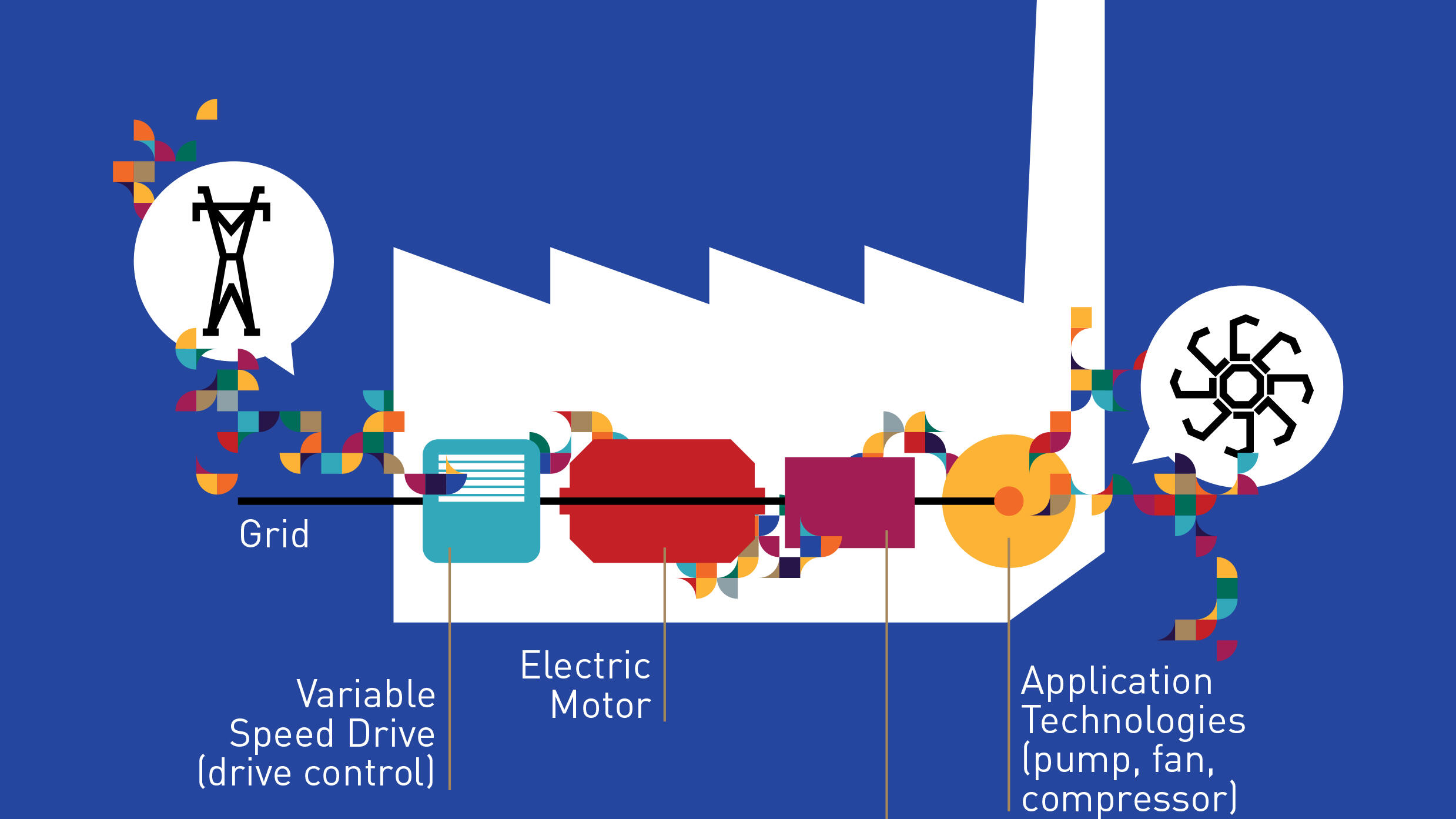

Read Full articleElectric Vehicles & Heat Pumps: Electric motors play a crucial role in the energy transition

Electric motors are implicated in two major decarbonisation options involving electrification: electric vehicles (EVs) and heat pumps. This will lead to a significant market growth, as well as growing…

Read Full articleCompressed Air: Energy efficiency at the top of the ComVac agenda (HM17)

The latest edition of ComVac will soon be staged: from 24 to 28 April 2017 in Hannover, Germany, under the umbrella of HANNOVER MESSE. All up, some 260 exhibitors will be there in halls 26 and 27 to…

Read Full articlewebinar: Enter the German market for industrial energy efficiency

Enter the German market for industrial energy efficiency (webinar) You are a provider of a great technology or service that increase energy efficiency in the industrial sector and want to enter the largest European market? In the webinar “Enter the…

DetailsNorsk Energi

Norsk Energi was founded in 1916 by the Norwegian industry to handle energy challenges on behalf of its members. Being by origin an association for more than 100 industrial and public enterprises, Norsk Energi is today a centre of expertise supporting all major sectors The staff of Norsk Energi consists of 80 engineers with a…

Energy Recovery in Metallurgical Industry

The paper describes the recovery of thermal energy from flue gas, combustion gas and waste heat from the process industry as well as in water tubes boiler, shell boilers and steam generators. 5 projects - Norway, Canada, Russia - showcase full engineering projects to upgrade existing plants, executed by Norsk Energi, a leading Norwegian centre of competence in the fields of energy, environment and…

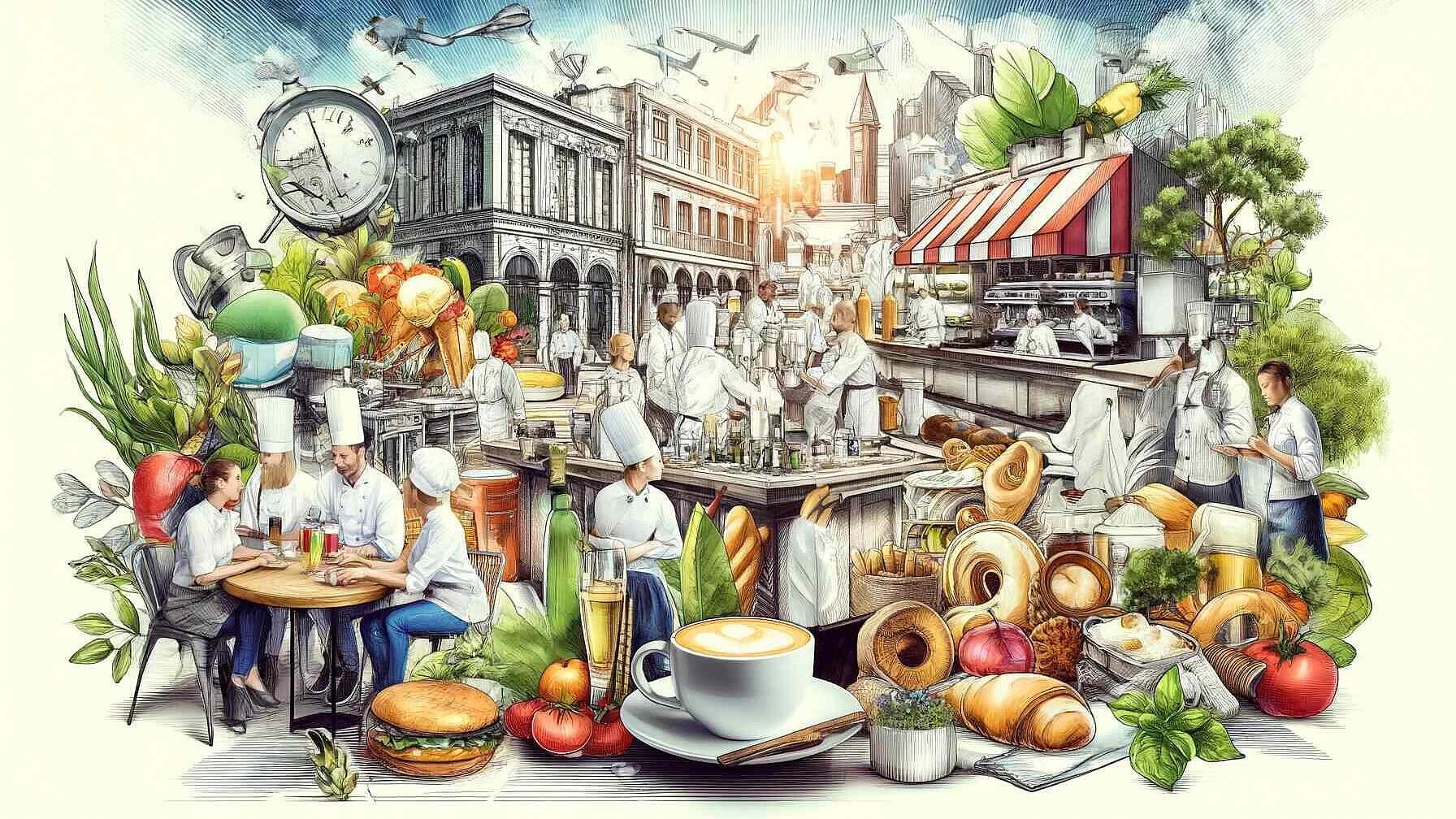

Read Full Business PracticeDecarbonising the European Food and Drink Sector: A Net Zero Roadmap

The Climate Challenge and Industry Impact The food and drink manufacturing sector in Europe is facing a significant challenge to reduce its greenhouse gas (GHG) emissions. Currently, this sector is…

Read Full articleIoT READY - Noise and Vibration System in waste heat recovery application

Just two pages describing a Noise and Vibration Guard system for an ORC waste heat recovery application of DeVeTec. It links to a recently published EEIP post on IoT is Today. We called it IoT READY as it shows the emerging remote control options in industrial processes.

Read Full Business PracticeThe Renewable Revolution: Powering Our Future

In a world grappling with climate change and energy security concerns, the transition to renewable energy has never been more crucial. Recent studies have shown that a 100% renewable energy system is…

Read Full article