Energy Efficiency

Energy EfficiencyBusiness Practices

Heatpumps - an overlooked opportunity?

Summary

Heat pump technology is well known for provision of heating, cooling and hot water to residential buildings in an efficient and reliable manner. Less known are the larger cousins of residential heat pumps -industrial and commercial units. They add an important factor to energy systems in cities, large buildings or industrial processes. In larger buildings, a smart, heat pump based energy management can distribute energy between parts of the building requiring heating and those in need for cooling. The effect is even bigger in industry, where industrial processes today run at temperatures below 100°C. An evaluation of the technical potential of heat pumps in industrial applications revealed an

an energy savings potential of 174TWh or about 10% of industry heating energy demand. The challenge is to connect application areas and find a use for waste heat from a cooling process or for waste cold from a heating process is the challenge. Sometimes it may just need some creative thinking, sometimes it can only be achieved by re-designing the whole process.

Open full article

Heatpumps - an overlooked opportunity?

Recover energy, don’t waste it!

What do a Norwegian fjord, a Belgian brewery, a Danish dairy plant, a Finnish data center, a German office building, and a French sports center (and many more) have in common? They use heat pumps – and nobody knows.

Heat pump technology is well known for the provision of heating, cooling and hot water to residential buildings in an efficient and reliable manner. Less known are the larger cousins of residential heat pumps –industrial and commercial units. While they also provide the same primary services, they add an important factor to energy systems in cities, large buildings or industrial processes: Large heat pumps close energy loops.

Wherever humans are active, they require energy. Energy always “flows” from a higher to a lower temperature level. The result is a surplus of energy at a level usually deemed not useful. In a typical residential building, the users need heating and cooling, lightning, entertainment etc. and while the inhabitants enjoy these services, energy is eventually lost. The same holds true for commercial buildings, hospitals, schools.

Heat pumps can provide energy, but they can also help reduce the absolute energy demand by being integrated into heat recovery systems. In larger buildings, a smart, heat pump based energy management can distribute energy between parts of the building requiring heating and those in need for cooling. This could also be done between different buildings.

The effect is even bigger in industry. Apart from the need to heat/cool buildings and to provide hot water for kitchen and showers, many industrial processes today run at temperatures below 100°C. This makes them suitable for the use of heat pumps. Prototypes can even provide temperatures up to 170°C. An evaluation of the technical potential of heat pumps in industrial applications revealed an energy savings potential of 174TWh or about 10% of industry heating energy demand. The savings amount is even larger, when considering the integration of cooling and refrigeration processes into the system.

|

Connecting the dots is a key challenge to fully use the potential.

Energy flows in industry are often complex. They require and provide energy at different times, locations and temperature levels as well as in in different quantities.

Every energy input results in waste energy at a lower level, every cooling/refrigeration processes produces waste heat and even if a heat pump is used for heating, it results in waste cooling. This energy can either be discarded to the environment or recovered to improve overall energy efficiency.

People need to understand this process to decide favourably for its imolementation. Experts responsible for designing and operating industrial processes also may not know about the opportunities. A typical comment of a plant manager was: “a by-product of our main process is energy at 50°C but it is useless to us. Even worse, it becomes a cost factor, as we have to invest in installations to get rid of it”.

The challenge is to connect application areas and to find a use for waste heat from a cooling process or for waste cold from a heating process is the challenge. Sometimes it may just need some creative thinking, sometimes it can only be achieved by re-designing the whole production process. If successful, efficiency improvements are tremendous. Up to an extend that the beneficiaries of these improvements do not want others to know; preferring to reaping the cost advantage for as long as possible.

Heat pumps are becoming state-of-the art in commercial applications

Office buildings, hotels, restaurants, hospitals, and sports facilities all need heating and cooling – quite often they require more heating than cooling. Most of them also need hot water for different purposes. Installing a heat pump as stand-alone solution or in a hybrid configuration is more and more common. Using only one machine to provide heating and cooling is economically even more efficient

Industrial Processes

Heat pumps can be applied in many industrial production processes. Application areas include:

- Heating / cooling of buildings

- Cleaning

- Drying – usually energy loops are closed by connecting the waste energy side to the source energy side and bridging the difference in temperature via the heat pump. If necessary, a fossil burner is added as back up energy source or to cover peak demand.

- Food production and processing (flakes, brewing, malting, fruit and vegetables, yeast noodles, potato as well as meat, milk and cheese),

- General production (such as textiles, timber industries, rubber and plastics, paper, brewing, malting brick production, and metal coating).

Connecting energy loops by using the waste energy from one process, shifting it to a useful level and providing it to another process is the wholy grail of efficient process design.

The following examples give insights into realized advantages of large heat pump installations in diverse application areas for office buildings, district heating, paper mill, hotles and dairy production. They can only be an inventive to consider heat pump applications further. To fully unleash this potential, it will not only require the industry to develop the technology even further, but also political clout, Policy makers need to create frameworks and markets that favor heat pump based systems as most sustainable solutions. They should favor energy demand reductuon using recovered energy in a similar manner as they favor the use of renewable energy today.

Last but not least, fixing the current market mechanism is the elephant in the room. Payback times of heat pumps that are acceptable to industry as well as availability of financing options depends largely on the comparison with cost of fossil fuel alternatives. If policy makers want to use the market mechanism for the energy transition, they need to set a correctice price signal.

Heads of states and governments have signed the COP21 agreements in limiting global warming to significantly below 2 degrees Celsius last december in Paris.

Making full use of the potential of large heat pumps in residential and commercial buildings, industrial processes and cities will make achieving this target much easier.But even more than that: a decarbonisation of the energy system is impossible without decarbonisation of the heating sector; a decarbonisation of the heating and cooling sector is impossible without heat pumps.

|

|

|

|

Background : Heat pump technology

Heat pumps convert air, ground heat and water into energy – it’s that simple! The general principle of the technology is identical and independent of application. A heat pump can provide heating, cooling and sanitary hot water for residential, commercial and industrial applications. Heat pumps transform energy from renewable energy sources (air | aerothermal, ground | geothermal and water | hydrothermal) into useful heat. They can also use recovered energy from industrial processes, infrastructure installations (sewers, subway, underground parking) or exhaust air from buildings. The transformation is done via the refrigeration cycle. It consists of a heat source, the heat pump unit and a distribution system to heat/cool the building, usually either air ducts or water pipes.

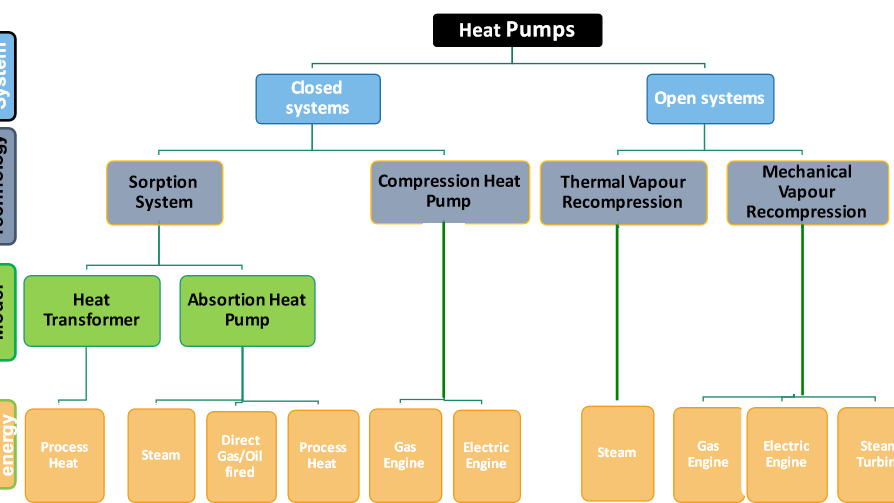

While a number of technical variations for heat pump technology exist, the electric compression cycle is most commonly used. In an electric compression heat pump a transfer fluid (refrigerant) transports the heat from a low energy source to a higher energy sink. Auxiliary energy - usually electricity or gas - is needed to run the compressor and the heat pumps.

The refrigerant cycle provides heating and cooling, continuously

Heat pump systems are optimized for heating or cooling. In heating mode, ambient energy is the heat source and the building/process is the heat sink. In cooling mode, the building/process is cooled down using the outside as the heat sink. Obviously, a system’s efficiency increases greatly in application areas with a parallel demand for heating and cooling giving such systems an additional economic advantage.

Positive side effects heat pump use are local employment, reducing import dependency, making energy cost more stable and predictable, and bridging the electric and thermal sectors by providing demand response potential and stabilizing the electric grid.

Heat pumps are cross-cutting the modern, future-oriented energy system. The required decarbonization of the energy system cannot be achieved without decarbonizing the heating sector. The heating sector cannot be decarbonized without heat pumps!

|

This article was first published in Revolve "Renewing Energy", Summer 2016