Search Result

Search ResultRevolutionizing Pump Systems: The Power of Life Cycle Cost Analysis

In today's competitive industrial landscape, optimizing operational costs while maintaining peak performance is crucial for success. One often overlooked area with significant potential for…

Read Full articleA systems approach to energy end use

The optimization of energy use in buildings and industry requires a systems approach to harvest its full potential. This idea is winning ground, as it is shown by the proposal of the ITRE committee of…

Read Full articleCompressed air - Hannover Messe 2017 follow up

Compressed-Air-and-Heat-System As a partner of leading global industry fair Hannover Messe, we are always spending a few days at the fair to "scout" some relevant technology and service solutions.…

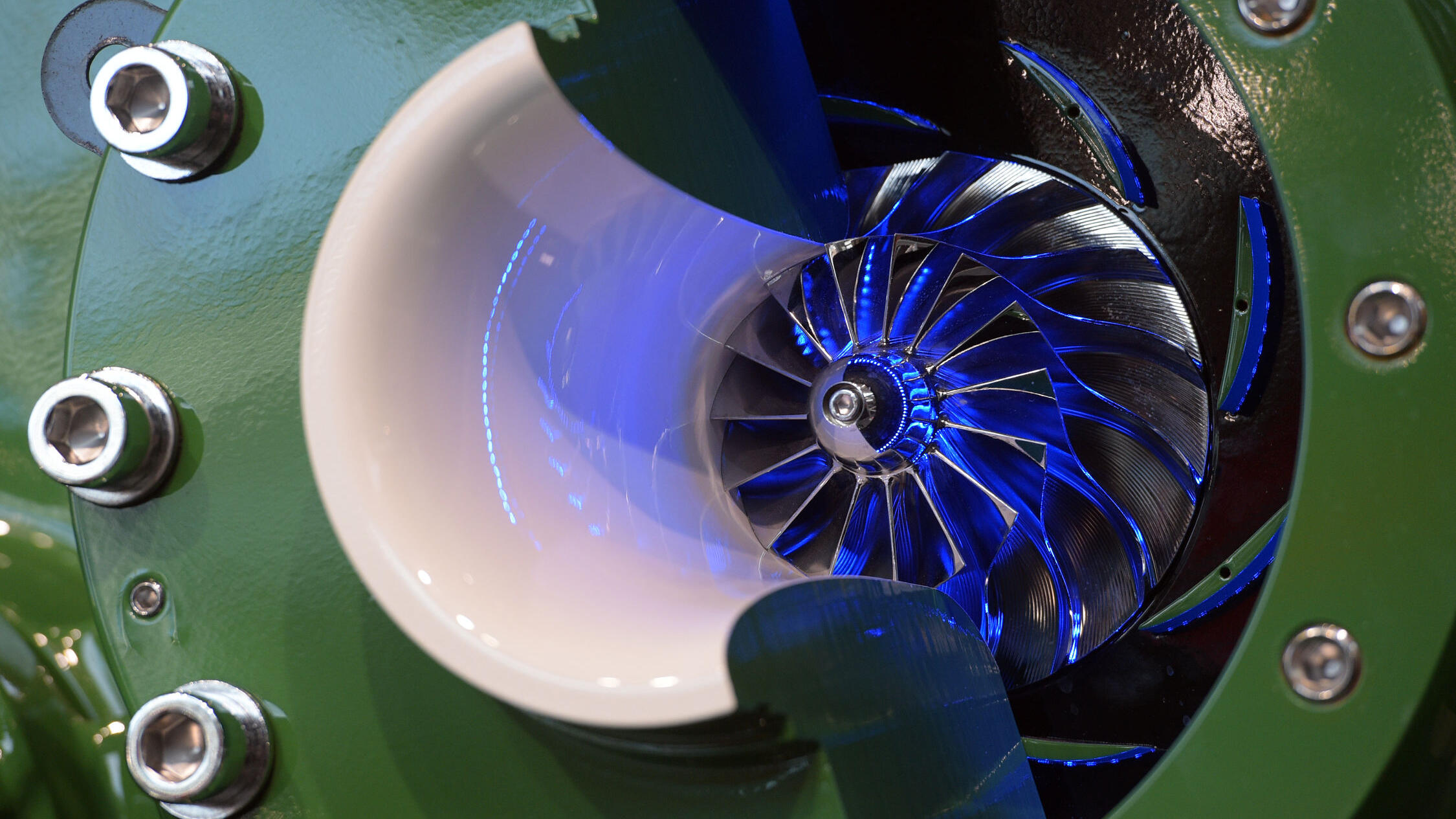

Read Full articleTop 5: How to increase energy efficiency of pumps – start with the system

Top 5: How to increase energy efficiency of pumps – start with the system Everybody knows that pumps consume a lot of energy. But do you know that pumps currently account for 10% of the world´s total…

Read Full articleTop 10 about Electric Motor Systems

In industry, electric motors are widespread and often hidden in closed systems such as fans, pumps or compressors. In the transition towards a zero-carbon energy system, the role of electric motors will grow even further. The technology to make motor systems more energy efficient is available on the market and its adoption is mostly beneficial from a life-cycle costing perspective.

Read Full Business PracticeBeverages: Gropper - oil free piston compressor for bottling

Case Study about planning and implementation of an energy efficient and flexible compressed air station. As the new plant was built from scratch, staff were able to fully exploit the potential of modern factory planning. Berthold Burgmeier, Head of Technology: “We plan and optimise our systems ourselves and efficiency, flexibility and economical energy consumption are extremely important to us.”…

Read Full Business PracticeHydraulic system - energy efficiency optimization

This paper describes the 4 step approach of KSB to optimize the energy efficiency of a hydraulic system. While focussing on the entire life-cycle, the aim is to lower operating costs. The approach starts with a system analysis to detect optimization potential and ends with usage of smart pump technology and services during operation - see also paper on industry 4.0 and smart pump technology. It…

Read Full Business PracticeWas bringt Energieeffizienz bei Pumpen

Welche Einsparungen lasssen sich mit effizienten Pumpen erreichen, welche Kapitalrenditen können erzielt werden. Welche Kosten fallen über die Lebensdauer einer Pumpe an und wie verhält es sich mit Life-Cycle-Costs vs. Anschaffungspreis. Das sind die Fragen, die EDUR beleuchtet. Sie können EDUR auch direkt auf der Hannover Messe ansprechen, Halle 15, Stand G 43.011 (Pavillion PumpeDe)

Read Full Business PracticePowering the Future: A Comprehensive Look at Hydrogen Production Methods

As the world grapples with the urgent need to transition away from fossil fuels and reduce greenhouse gas emissions, hydrogen has emerged as a promising clean energy carrier. But not all hydrogen is…

Read Full articleChoosing the best techniques for waste heat recovery

Choosing the best techniques for waste heat recovery Darren Bryant, CEO of Heatcatcher UK, discusses best available waste heat recovery techniques for the glass industry and outlines UK government…

Read Full article