Search Result

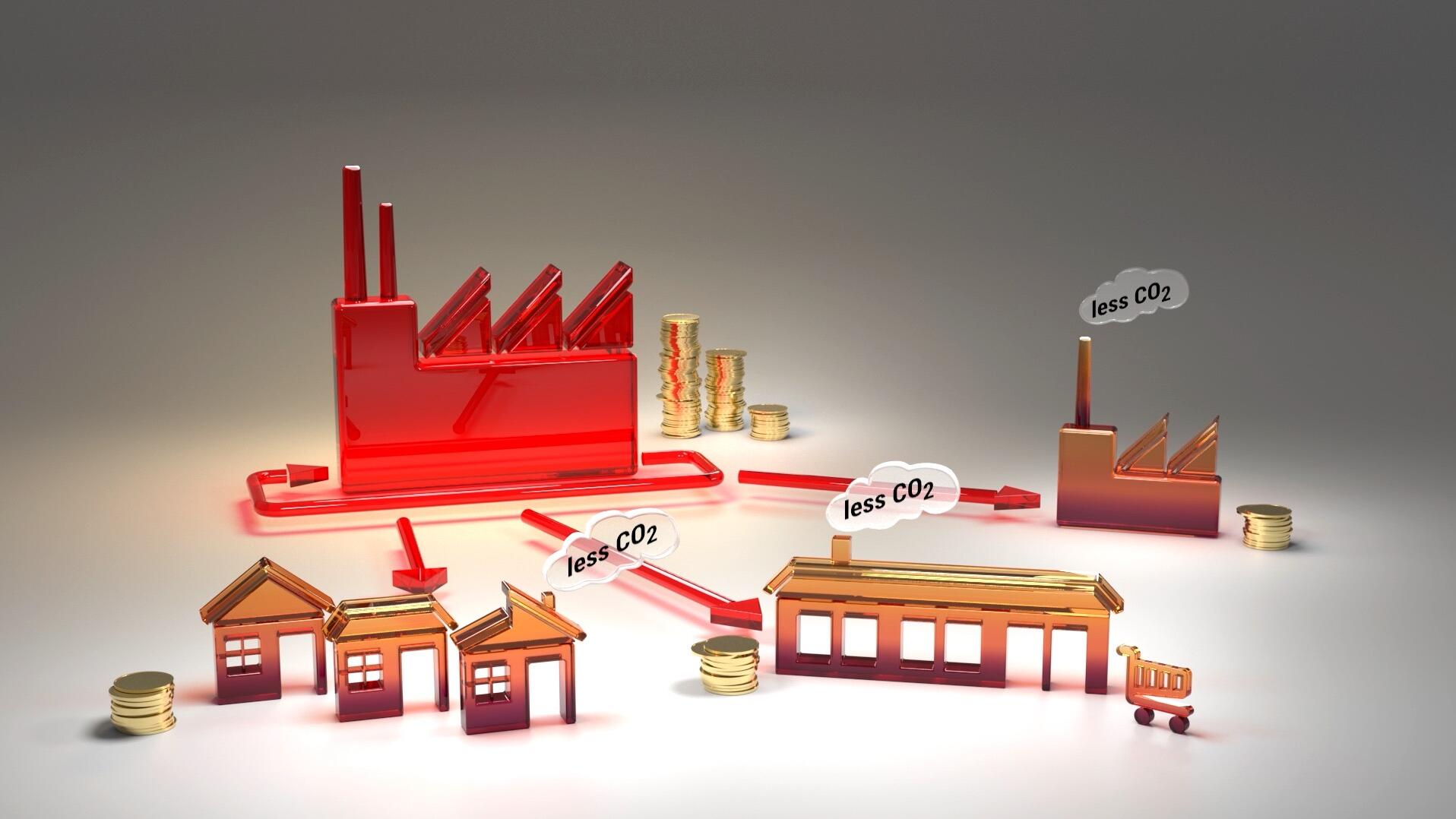

Search ResultSignificant cost savings & lowered CO2 Emissions through efficient Heat-Recovery Solutions

Marc Delannoy, General Manager Airflux: “Airflux selected SWEP as a partner for two main reasons. First, SWEP is a well-known brand, appreciated in the heat exchange industry. Furthermore, one of our main partners was already successfully integrating SWEP's brazed plate heat exchangers in their systems. We have had a positive experience of integrating SWEP heat exchangers into our customers'…

Read Full Business PracticeETEKINA FINAL CONFERENCE

Presenting the key results of the EU-funded ETEKINA project on the development, construction and comissioning of three prototypes of new heat pipe heat exchangers (HPHE), recovering more than 40% of waste heat streams in energy intensive industries.…

DetailsThe transformation of energy intensive industries

The latest records are mind-blowing: up to 50% energy savings and possibly even more. During the last 4,5 years new heat pipe heat exchangers were implemented at three industrial demo-sites: an…

Read Full articleDirty Truth about Heat Exchangers

In this article, Matt Gutschow, co-founder of HeatCalc, provides some insights into the topic of heat exchanger fouling. What is fouling? What are the effects and what are solutions to prevent or at least control fouling in energy recovery projects using heat exchangers. Matt built his insights on the basis of hundreds of heat recovery projects in industry he has investigated over previous years.

Read Full Business PracticeHow reusing waste heat can take aluminium one step closer to becoming a greener industry

Aluminium is one of the most recycled commodities in the world, but the processes involved in the production of this metal still leave a high environmental impact on the planet. New waste heat…

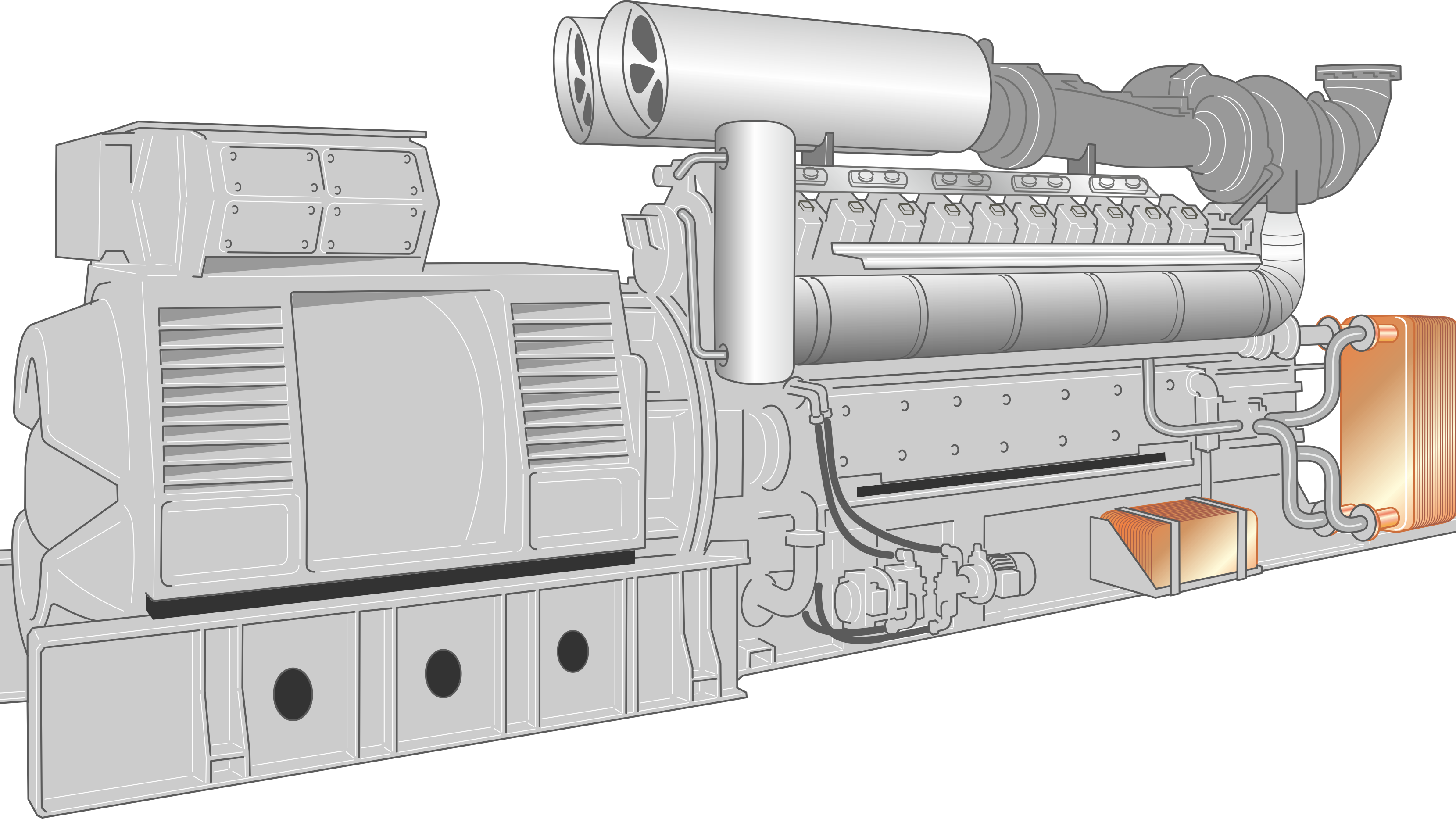

Read Full articleUtilize all the available energy — Heat recovery

Today, global industry consumes a vast amount of energy. The biggest challenge is that as much as half of it is wasted due to the inefficient and complicated recovery of low-grade energy. Heat in the…

Read Full article5 energy sources you have never thought of

Every day, surplus heat is released into the environment, contributing to global warming and wasting chances of clean energy generation. Opportunities to recover and reuse it can be found in places…

Read Full articleSmall systems, big benefits

How the heat pipe heat exchangers designed by ETEKINA partners are shaping the waste heat recovery systems of the future. In early February this year, the cost of carbon reached record highs with…

Read Full articleRecycled factory heat benefits industries and the environment

Industrial processes account for more than a fourth of Europe’s primary energy consumption and produce a tremendous amount of heat. EU funded research is closing the circle with novel systems that…

Read Full articleHow waste heat recovery will change the landscapes

Each year industries across Europe allow a valuable source of heat energy to simply escape out their chimneys. An EU-funded project called ETEKINA has reimagined a decades-old technology called heat…

Read Full article