Search Result

Search ResultWhat is cold local heat?

At first glance, it sounds strange when cold local heating is to take over the heat supply. Is that a contradiction? No, cold heat really does exist. It is a heat supply with relatively low…

Read Full articleBridging the industrial heat divide

Between industrial heat owners and relevant solution providers While I was running a sales team for a product that recovered heat and converted it into electricity, I would get daily inquiries from…

Read Full articleIndustrial heat: An emission free energy source

Heat is a form of energy that is all around us. There’s heat from the sun (solar thermal), and from the earth (geothermal), but for this post, I want to talk about industrial heat - heat that is a…

Read Full articleAll you need to know about advanced high temperature heating technologies for industry

Decarbonising industry means the decarbonisation of electricity and heat. In principle, industry can rather easily decarbonize their electricity consumption, just buy green electricity. Heat is the…

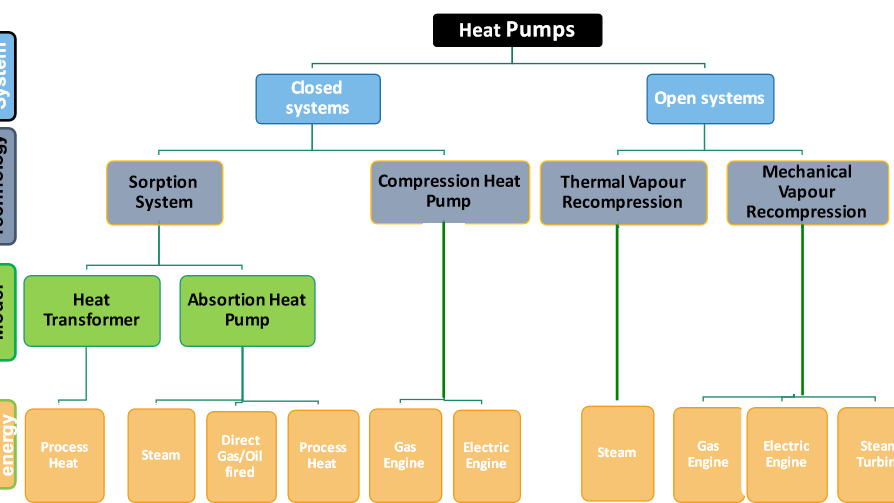

Read Full articleHeatpumps - an overlooked opportunity?

Recover energy, don’t waste it! What do a Norwegian fjord, a Belgian brewery, a Danish dairy plant, a Finnish data center, a German office building, and a French sports center (and many more) have in…

Read Full articleHeatpumps: vision vs. reality

Vision vs. reality – why political intervention is essential to unleash heat pumps energy savings potential in industrial and commercial applications. Buildings need a comfortable indoor temperature…

Read Full articleHow reusing waste heat can take aluminium one step closer to becoming a greener industry

Aluminium is one of the most recycled commodities in the world, but the processes involved in the production of this metal still leave a high environmental impact on the planet. New waste heat…

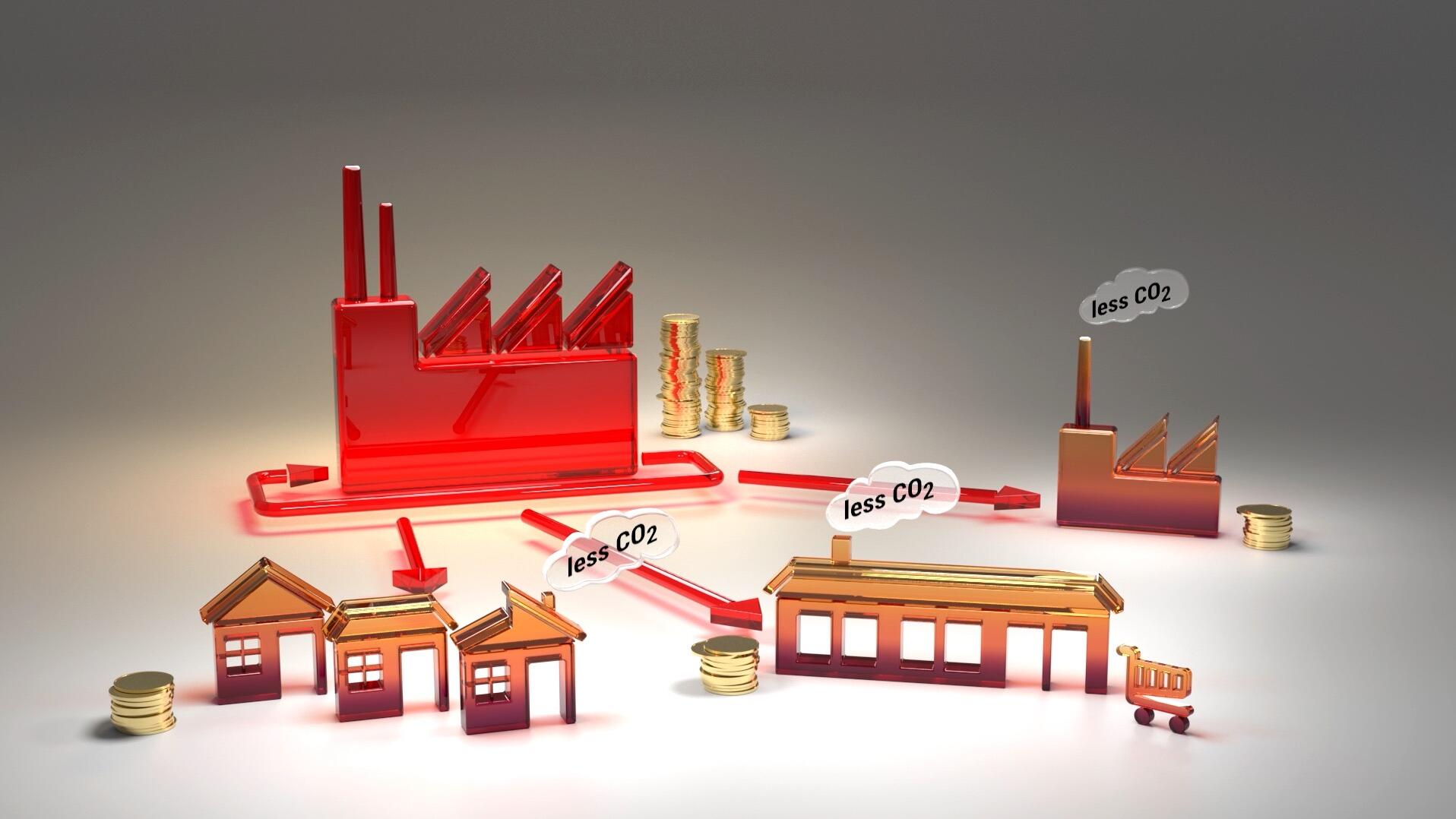

Read Full articleRecycled factory heat benefits industries and the environment

Industrial processes account for more than a fourth of Europe’s primary energy consumption and produce a tremendous amount of heat. EU funded research is closing the circle with novel systems that…

Read Full article5 energy sources you have never thought of

Every day, surplus heat is released into the environment, contributing to global warming and wasting chances of clean energy generation. Opportunities to recover and reuse it can be found in places…

Read Full articleHEAT PUMPS IN THE EUROPEAN UNION 2022 - status report

This report is an output of the Clean Energy Technology Observatory, which is being implemented by the European Commission’s Joint Research Centre on behalf of its DG Research and Innovation, in…

Read Full article