Energy Efficiency

Energy EfficiencyIndustrial motors energy saving potential: 5 nuclear power plants!

Summary

In 2015 the energy saving potential using VSD would amount to 71 TWh across all industry sectors. VSD will only be broadly implemented if it is technically meaningful and economically viable! In industry, there is a significant amount of rotary machines of various types such as electric motors on the one hand, and on the other hand loads which are pumps, fans, compressors. Many of industry players all agreed on the fact that VSD has many advantages. And it is true that it can not only save from 15 percent up to 40 percent of energy but also it extends equipment lifetime thanks to its soft start-

up/shutdown function. And there are further beneficial aspects: the potential of extending the life of the equipment and the reduction of greenhouse gases. Still, many question remain unanswered... What is the time plan? And the impact of "locked investments"=exixting NON VSD will take to fully leverage the energy savings potential.

Open full article

Industrial motors energy saving potential: 5 nuclear power plants!

What is said about the energy saving potential of VSD (variable speed drive) in industry?

- Replacing conventional motors by those with variable speed would save about 41 percent of the energy used in industry. (source)

- Energy savings potential for motor systems in the European Union is estimated to 50 Billion kWh/year - with Germany alone being able save 10 Billion kWh/year (source)

- In 2015 the energy saving potential using VSD would amount to 71 TWh across all industry sectors. (source)

We will see what happens in the near future if they were right.

Besides the macro-perspective, let's have a closer look on the technical and economical side. What remains true is that VSD will only be broadly implemented if it is technically meaningful and economically viable!

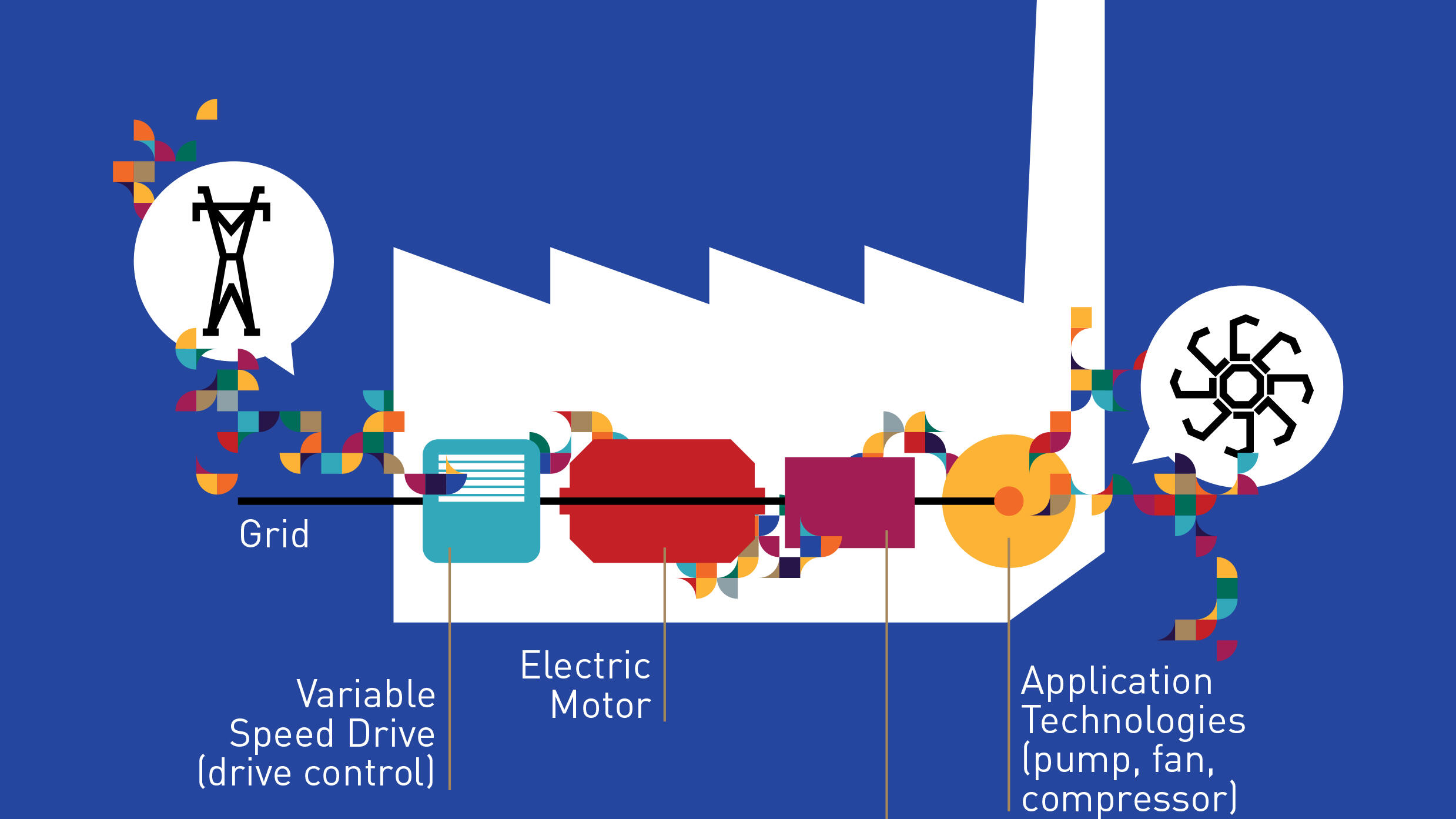

Where VSD can be implemented in industry...-nearly everywhere!

In industry, there is a significant amount of rotary machines of various types such as electric motors on the one hand, and on the other hand loads which are pumps, fans, compressors...which are coupled to the motor to form a rotary system.A common factor in these machines is that they are mostly designed for rotation at constant speed and therefore provide a constant output. Thus they rotate at 100 percent of speed for short duration.

This means, they are most of the time not effectively using energy. And - "side effect"- this energy waste increases carbon emissions. This has led to the idea of using variable speed machine processes with VSD motors.

Many of industry players all agreed on the fact that VSD has many advantages. And it's true.

Indeed,...

- Electric motors consumption represents up to 75 percent of total plant's energy consumption

- Additionnally, two-thirds of motorized equipment need to work at variable speed e.g pumps, fans, compressors.

VSD systems can not only save from 15 percent up to 40 percent of energy but also it extends equipment lifetime thanks to its soft start-up/shutdown function.

How it works?

Basically, VSD systems consist of three basic components: the electric motor, the power converter, and the control system.

- The electric motor is connected directly of indirectly to the load

- The power converter controls the power flow an AC supply (often via a supply transformer) to the motor by

- Appropriate control of power semiconductor switches which are part of the power converter.

VSD are also known as VFD, ASD... which are somehow similar in opeation principle.

And the economic side of VSD?

There is always a case by case story. But the story behind is simple as this example shows:

- considering a system of 12-pulse/200Hp drive with a total value of 51,000 $ with 20,000 $ for the 200 Hp constant speed motor and 31,000 for the ASD system cost.

- The installed ASD system would save energy cost of 17,590 $ annually.

Although this is only an indication , it shows that it is possible to have a payback after 15 months assuming total net cost installation of 21,210 $ as an example.

And there are further beneficial aspects:

- the potential of extending the life of the equipment and

- the reduction of greenhouse gases.

Conclusion

VSD are key tools for an industry that is strongly motorized and automated. They deliver multiple benefits ranging from lower total cost of ownership via energy cost reduction, longer life-time as well as a reduction of greenhouse gases.

And there is still huge potential!

Still, many question remain unanswered...

- What is the time plan?

- How long it will take to fully leverage the energy savings potential of VSDs?

- What is the impact of "locked investments"=exixting NON VSD motors in place?

- What is the annual replacement rate of the electrical motors in the industry and can this rate be accelerated?

Enough questions for follow up post on electrical motors - stay tuned.