Circular Economy

Circular EconomyCircular Economy

How reusing waste heat can take aluminium one step closer to becoming a greener industry

New waste heat recovery technologies can take the industry one step closer to achieving cleaner production methods. Aluminium is the second most highly produced metal and one of the most recycled commodities in the world. In some industries, over 90% of it is recycled and 75% of aluminium ever produced is still in circulation today. The production of aluminium leaves footprints on the environment that include acidification emissions. Recuperators, air preheaters or heat pumps are some of the alternatives they mention. heat pipes heat exchangers are the heart of the ETEKINA project, which aims to recover more than 40% of of accessible waste heat content in streams lost to atmosphere from energy intensive industries. The process requires such an intensive level of energy that, in the United States, it consumes approximately 5% of all the electricity generated in that country, according to the American Aluminium Association. Most of the processes use high temperatures, which means that a big share of this energy.

Read Full articleFour young scientists talk about the future of waste heat recovery

Scientists in four European countries have been working on the ETEKINA project. They have developed three new heat pipe heat exchangers (HPHE) They aim to recover between 57% and 70% of waste heat streams in three specific sectors.

Read Full articleFinding new players in an old market: the energy potential of a Swedish case study

The EMB3Rs platform will help a district heating company in Sweden identify the most efficient way of connecting medium-sized non-traditional excess heat providers to a mature network. A big part of this achievement is due to an extensive network of local district heating.

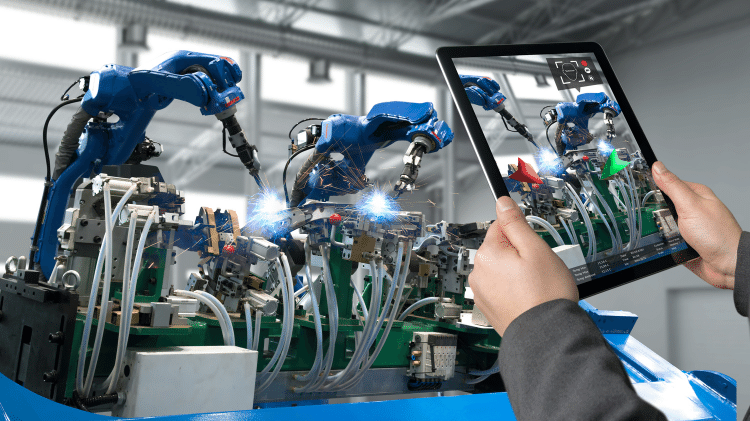

Read Full articleIndustrial processes going digital

Digital solutions make every industrial step efficient even in situations where they could hardly be completed. The European Commission is not responsible for any use that may be made of the information it contains. This project has received funding from the European Unions Horizon 2020 research .

Read Full articleEurope’s energy-intensive industries coping with covid crisis while trying to stay on sustainable path

Europes industry has significant challenges today. All Europeans also have to cope with the COVID-19 crisis and with a paralysed economy. There are also discussions within the EU institutions and through various consultations on the recovery package and what that will mean to.

Read Full articleReducing emission from cement and steel manufacturing

Electricity is versatile in terms of its potential uses, but some industrial processes will be difficult to decarbonise. Cement, steel and plastics manufacturing, in particular, pose major challenges. Emissions from cement manufacture could be reduced by as much as.

Read Full articleEscaping the horns of a dilemma

Zen and the Art of Motorcycle Maintenance has written a blog about the hydrogen economy. He argues that electrifying everything is the right way to go. Using hydrogen in the gas grid is an understandable effort by the gas industry to maintain their position.

Read Full articleORC-systems are helping to create a sustainable energy future

Organic Rankine Cycle (ORC) technology is being used in Sweden to transform waste heat into renewable electricity. The high efficiency and low maintenance way to produce sustainable electricity is being adopted by district heating systems around the world. Read how Ronneby.

Read Full Business PracticeRank Organic Rankine Cycle Technology with applications in Heat Recovery solution

ORC RANK has worked with SWEP to implement a heat recovery solution for electricity power generation. The activation range for the low-temperature equipment starts at just 85 °C. SWEPs heat exchangers are installed as economizers,.

Read Full Business PracticeShining a light on Tomatoes

Royal Pride Holland is using the J624 GS engines to power the greenhouses new cogeneration plant. Some of the power generated is used for lighting for the tomatoes, but most is supplied to the public power grid. The overall level of efficiency.

Read Full Business Practice