Circular Economy

Circular EconomyCircular Economy

An Uber for heat: How a new platform can help industries reuse excess heat and meet decarbonisation goals

Mafalda Silva is a Senior Researcher at the Institute of Science and Innovation in Mechanical and Industrial Engineering. She has participated and managed multiple projects concerning energy planning and sustainability. Silva has developed a heat and cold matching platform that determines the costs and benefits related to excess heat utilization routes for the industry and end users. The EMB3Rs project is ending soon, but Silva would like it to be used as much as possible by the different target stakeholders and hopefully become a reference tool in the field. The platform will remain available and accessible online at least over the next five years. The project has also created several resources to support its continued use, such as manuals and a video tutorial that will be accessible through the project website once they are approved.

Read Full articleEmissions Impacts of Alternative Fuels Combustion in the Cement Industry

The study analyzes alternative fuel impacts on U.S. cement industry emissions, finding marginal CO2 reductions and variable non-CO2 pollutant changes. Fuel types examined include waste and biomass, with a focus on CO2, SO2, NOx, and PM emissions across different replacement scenarios.

Read Full articleTransitioning industrial zones into hubs for circularity

The Horizon-Europe IS2H4C project, coordinated by Devrim Murat Yazan, University of Twente, and funded with 23.5 million euros, aims for systemic industrial symbiosis across Europe, targeting zero emissions and sustainable practices in various industries through innovation and the collaboration of 35 partners.

Read Full articleDecarbonisation of industrial heat: The iron and steel sector

Achieving deep decarbonisation by 2050 is only possible through new production processes. Electricity demand of the sector could increase three-fold by 2050. The production of steel from recycled scrap increases by a range of +30% to +70% versus.

Read Full articleWater & energy reuse: from waste to resource

Alufluor collaborated with the EU's iWAYS project to optimize resource recovery, focusing on reducing emissions and recycling. The initiative introduced technologies to conserve water and energy. The partnership aims to enhance sustainability in European industries without compromising economic progress.

Read Full article‘Uber’-like platform to match heat supply and demand released

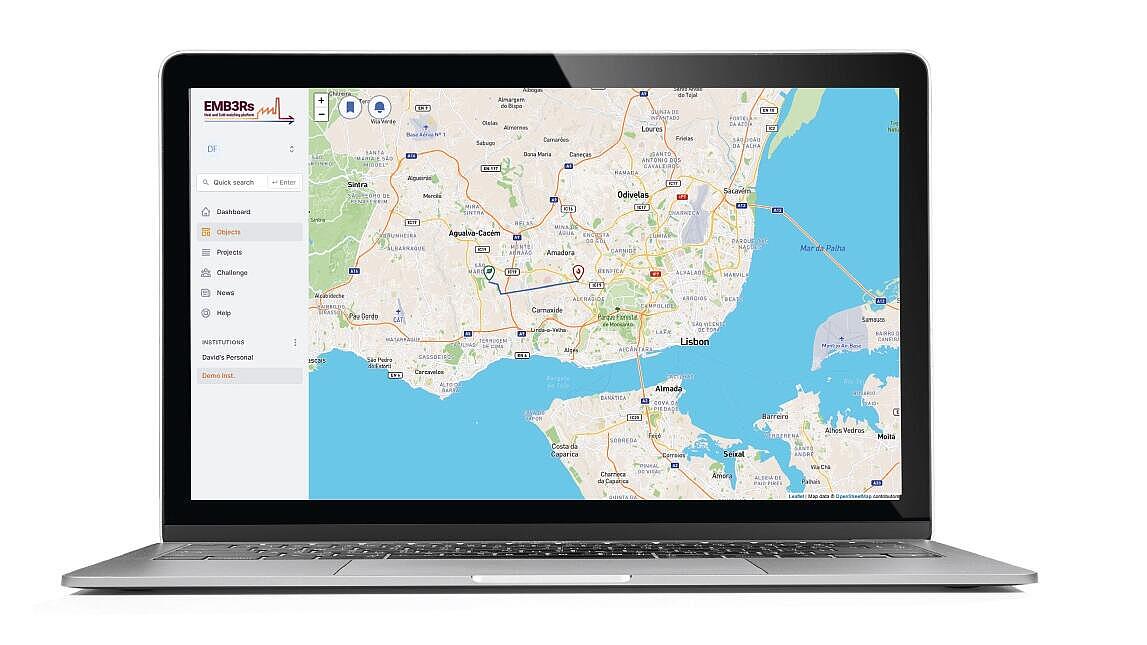

Until now, there was no efficient way for industries generating excess heat to provide it to nearby users who need it. Now the EMB3Rs platform, a tool that matches thermal energy sources with potential demand, offers an effective way for these heat sources and sinks to find each other.

Read Full articleVideo relased: A platform to calculate energy recovery options

The final video about EMB3Rs heat and cold matching platform has been released. It features the different application options for the platform. Discover four case studies in Portugal and Greece, take a visit at the platform developers office and listen to what the coordinator.

Read Full articleDistrict heating: balancing green energy with end-user needs

District heating companies are serving both energy supplier and end-user. Rising energy prices and carbon targets mean it is no longer sustainable or affordable to run our district heating systems on gas.

Read Full articleWaste heat: recovering a valuable renewable resource

EMB3Rs is an open-source, excess heat/cold re-use matching platform. It determines the costs and benefits of re-using industrial waste heat energy. The platform matches heat sources with sinks, to reduce carbon emissions.

Read Full articleDeep decarbonisation of industry: The cement sector

Fossil fuel combustion to meet heating needs accounts for 35% of cements CO2 emissions. The remaining 65% are due to direct process emissions, which must also be addressed. By 2050, cement production in the EU is expected to remain below pre-2010 levels.

Read Full article