Circular Economy

Circular EconomyCircular Economy

Carbon dioxide emissions are a common issue for many intensive-energy industries. But Ceramics companies are increasingly turning to creative solutions to reduce their climate footprint. Ceramic tile manufacturing industry does not have a reputation for being exactly environmentally friendly. In Spain water scarcity issues have driven the industry to use part recycled water and part drinking water. The European ceramics industry is experimenting with heat pipe heat exchangers (HPHEs) to recapture energy lost from piping hot kilns and transferring that energy to another point in the production chain, rather than dispose of the heat, Ceramiche Atlas Concorde The HPHEs being developed as part of ETEKINA project will help with this. It is not a breakout in technology, it is not like going to the moon, said Luca Manzini, said Manzini. She expects that the initiative will result in savings of between €120,000-180,000 cubic metres of natural gas.

Read Full articleRecycled factory heat benefits industries and the environment

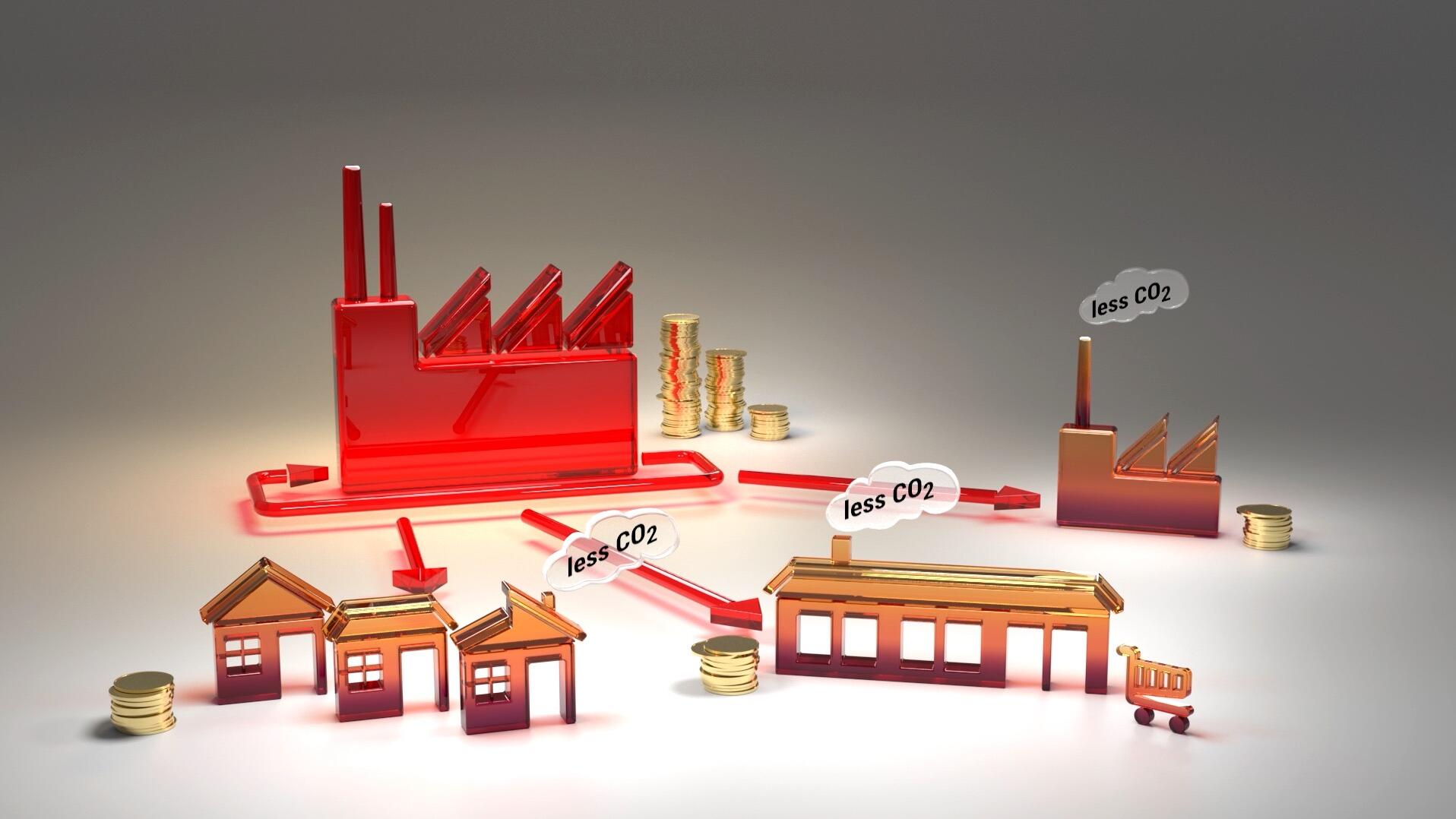

EU funded research is closing the circle with novel systems that recover waste heat and return it for reuse. Most process heat is lost to the environment as exhaust or discharge streams. Recovering and reusing this heat reduces energy consumption, emissions and pollutants.

Read Full articleSummertime is installation time

Engineers use summer break to launch new heat recovery system. ETEKINA heat pipe heat exchangers (HPHE) designed for one of the furnaces unit is fully functional and full scale prototype intended for energy-intensive industries.

Read Full article5 energy sources you have never thought of

Less than 30% of the energy consumed on the planet is converted efficiently. The rest is discharged into the atmosphere in the form of waste heat. Excess heat produced by chillers in a supermarket can end up providing space heating and hot water for flats.

Read Full articleOn the road to making ceramic production greener

Ceramic production has had a bad reputation when it comes to environmental issues. But that is starting to change. Gabriele Frignani is responsible for applied research at SACMI FORNI SpA*,. He is co-ord.

Read Full articleMapping energy use for a fossil fuel-free Europe

Heat Roadmap Europe provides the data that engineers need to decarbonise heating and cooling systems. The project has inspired EMB3Rs and is redesigning our energy sector. Heating and cooling is probably the most diverse sector of Europes energy system.

Read Full articleWhy would you use hydrogen for power generation?

SSE and Equinors plan to build a hydrogen power station in the UK. To help navigate this topic I have provided a guide to hydrogen colours. It does not seem to make too much sense to use electricity to make hydrogen to then convert it.

Read Full articleHPHE and greener furnaces: a combo that can make emissions plunge in the aluminium industry

Insertec is a leading manufacturer of industrial furnaces based in the Spanish province of Biscay. It is a crucial partner in one of the three case studies where ETEKINA is testing a new range of heat pipe heat exchangers.

Read Full articleHow data can increase the re-use of waste energy

EnergyLab Nordhavn sits on the edge of Copenhagen, overlooking the Øresund Strait. The large-scale research and demonstration project has been a hive of activity for the last five years. It is based on Copenhagens power.

Read Full articleWhat is cold local heat?

Cold local heating is a heat supply with relatively low temperatures. The principle of heat supply is particularly interesting with regard to climate protection. It allows waste heat from industry or renewable energies to be used. There are no or only minor losses in the pipeline.

Read Full article