Search Result

Search ResultRank Organic Rankine Cycle Technology with applications in Heat Recovery solution

In a project involving ACCIONA and KEROS CERAMICA, RANK has worked with SWEP to implement a heat recovery solution for electricity power generation. ORC RANK equipment capacities range from 2 to 100 kWe. The activation range for the low-temperature equipment starts at just 85 °C.SWEP's heat exchangers are installed as economizers, evaporators and condensers.

Read Full Business PracticeChoosing the best techniques for waste heat recovery

Choosing the best techniques for waste heat recovery Darren Bryant, CEO of Heatcatcher UK, discusses best available waste heat recovery techniques for the glass industry and outlines UK government…

Read Full articlePioneering the Path to Net Zero: Decarbonizing Heat in the Food and Drink

Evolving Climate Goals and the Heat Challenge In 2015, the UK government published a roadmap for decarbonizing the food and drink sector, highlighting a potential reduction in emissions from…

Read Full articleHPHE and greener furnaces: a combo that can make emissions plunge in the aluminium industry

Furnaces can account for more than 70% of energy consumption in plants dedicated to secondary aluminium production, releasing 25%-35% of the heat they generate. This is why Insertec , a leading…

Read Full articleBridging the industrial heat divide

Between industrial heat owners and relevant solution providers While I was running a sales team for a product that recovered heat and converted it into electricity, I would get daily inquiries from…

Read Full articleEnergy Optimization using Artificial Intelligence (AI) on HVAC system

Heating, Ventilation, and Air Conditioning (HVAC) systems accounting for substantial energy consumption up to 40% of total energy consumption in buildings, no matter the type of building as a…

Read Full articleThe transformation of energy intensive industries

The latest records are mind-blowing: up to 50% energy savings and possibly even more. During the last 4,5 years new heat pipe heat exchangers were implemented at three industrial demo-sites: an…

Read Full articleCase study: Monitoring and Targeting method applied in automotive industry

Case Study of the implementation of the Monitoring and Targeting method to optimize the heating system in a body shop of an automotive producer. Starting with an in-depth explanation of the methodology, the case study shows how the methodology was applied - from analytical findings to financial impact. According to HE Consulting, this methodology is an appropriate tool to achieve savings through…

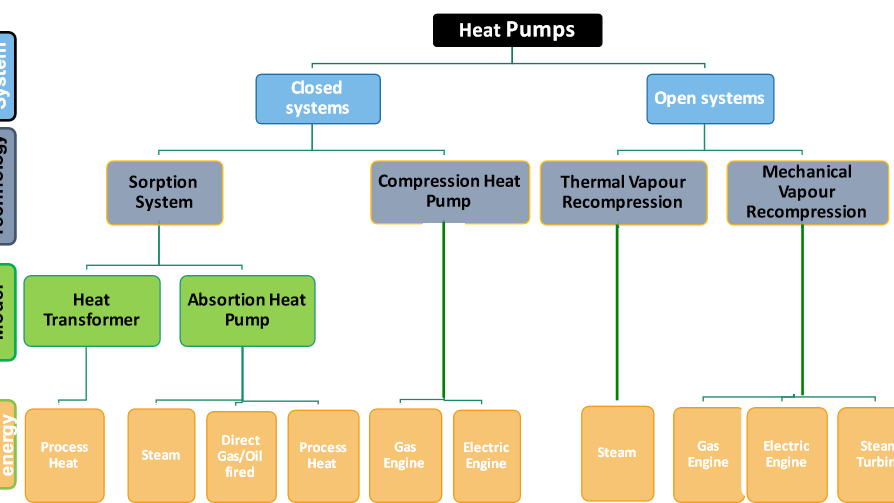

Read Full Business PracticeHeatpumps: vision vs. reality

Vision vs. reality – why political intervention is essential to unleash heat pumps energy savings potential in industrial and commercial applications. Buildings need a comfortable indoor temperature…

Read Full articleA catalogue of energy efficiency measures for supermarkets

The SUPER-HEERO project, co-funded by the European Commission under Horizon 2020 Programme, aims at providing a replicable financial scheme for energy efficiency investment in small and medium…

Read Full article