Search Result

Search Result45% TCO - Industrial Pumps fight for efficiency: Part 2/4

Increase efficiency : focus on 2 components In my first pumps-post « 45% TCO – industrial pumps fight for efficiency » I introduced the topic related to energy efficiency improvement for industrial…

Read Full articleHeidelberger Druck - cooling lubricant pumps

Short case study describing how Heidelberger Druckmaschinen AG saved 90% of energy in there cooling lubricant circuit leading to a pay-back of far below 2 years. This was achieved by replacing the entire pump system and a modernization of the control system, activities which have resulted from applying the KSB energy efficiency concept FluidFuture. For detailed information of this concept, please…

Read Full Business PracticeOptimizing Electrical Motor Efficiency: Get More Bang for Your Buck

First published here . Electrical motors are devices that convert electrical energy into mechanical force. They operate on the principles of electromagnetism, using the interaction between winding…

Read Full articleThe benefit of compressed air systems becoming smart - a Boge example

The continuous improvement programme – a smart service – considerably improves the efficiency and life cycle of compressed air systems based on continuous Improvements. The origin of the revolution Up…

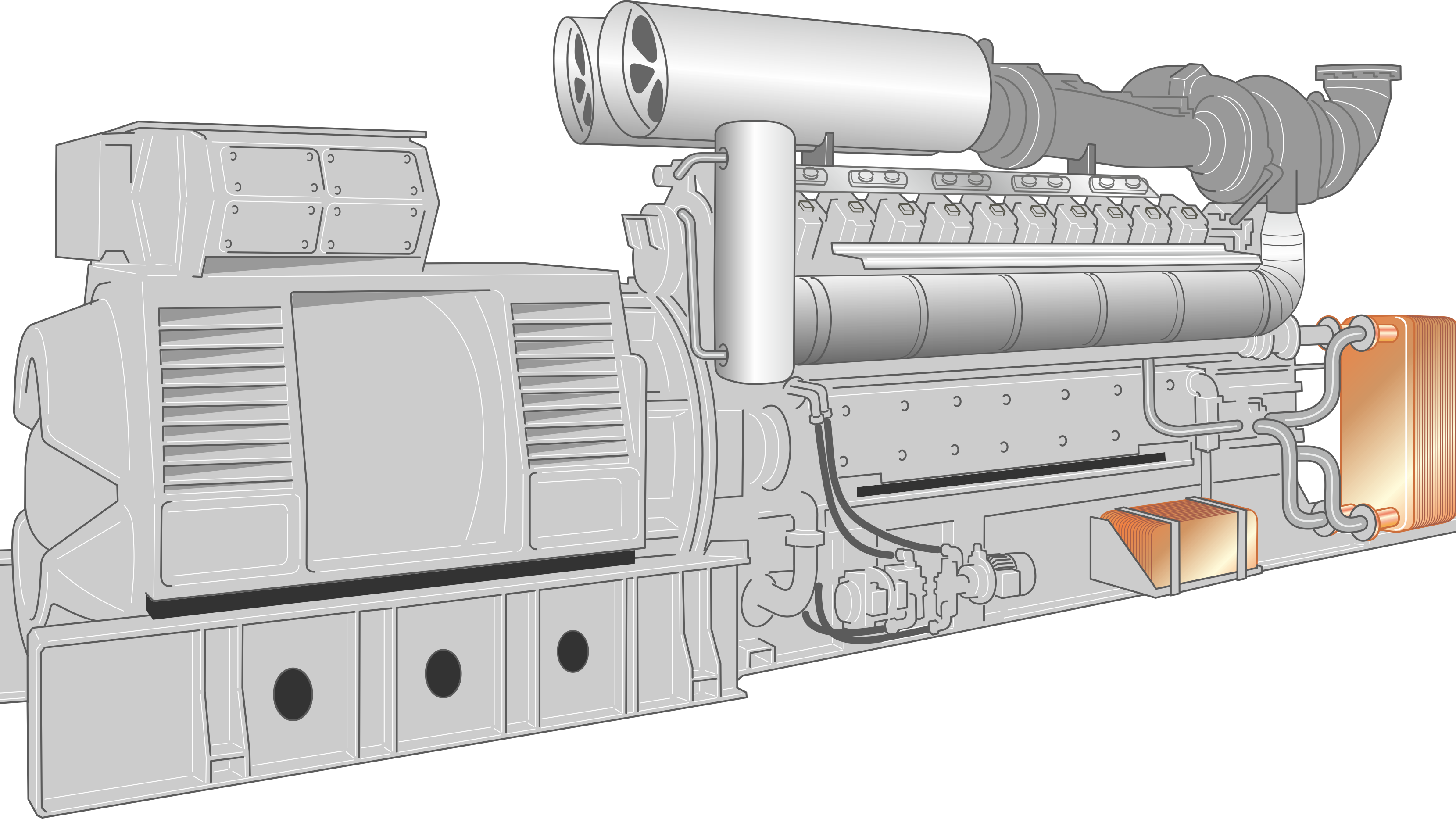

Read Full articleUtilize all the available energy — Heat recovery

Today, global industry consumes a vast amount of energy. The biggest challenge is that as much as half of it is wasted due to the inefficient and complicated recovery of low-grade energy. Heat in the…

Read Full article