Energy Efficiency

Energy EfficiencyEnergy Efficiency

The paper details Professor Hussam Jouhara's work on the Heat Pipe Condensing Economiser (HPCE), a technology created under the iWAYS project funded by the EU's Horizon 2020 program. The HPCE is designed to reduce industrial energy consumption and emissions by recovering waste heat and water from factory exhausts, thereby improving efficiency and environmental friendliness. A key challenge faced in the development was the variability of exhaust stream compositions, which was addressed through accurate chemical measurements and by designing a system to treat corrosive acidic condensates. The HPCE is capable of recovering up to 80% more heat than plants without this technology and also recaptures vaporized water, contributing to reductions in carbon footprint and water wastage. This system has been successfully implemented in a harsh industrial environment at the Alufluor demo site in Sweden, aiming to recover at least 40% of the total energy consumed. The HPCE offers a more controlled emission process, beneficial especially to the regulated chemical industry due to its added energy efficiency and material recovery potential. Jouhara aspires for widespread adoption of this technology, envisioning factories without chimneys emitting only safe gases, making significant environmental improvements.

Read Full articleDigital Transformation in Industrial Energy Efficiency: Insights for European Companies

European industries use digital tools for energy efficiency, as per a report with nine case studies, highlighting big data, AI for maintenance, demand response programs, collaboration importance, addressing high costs, and skill gaps, offering guidance for integrating technologies and fostering innovation for sustainability.

Read Full articleElectrifying Industry: The Path to Decarbonizing Process Heat

The Agora Industry study outlines direct electrification's potential to fulfill 90% of industry's non-electrified energy demands in Europe by 2035, highlighting a key opportunity for CO2 reduction and progress towards EU climate targets.

Read Full articleQuiz Your Way to Energy Mastery! Discover, Learn, and Win with EnerWhizz

EnerWhizz is a mobile quiz game designed to teach players about energy efficiency and renewable energy in an engaging and competitive format, offering rewards, multilingual support, and opportunities for global competition.

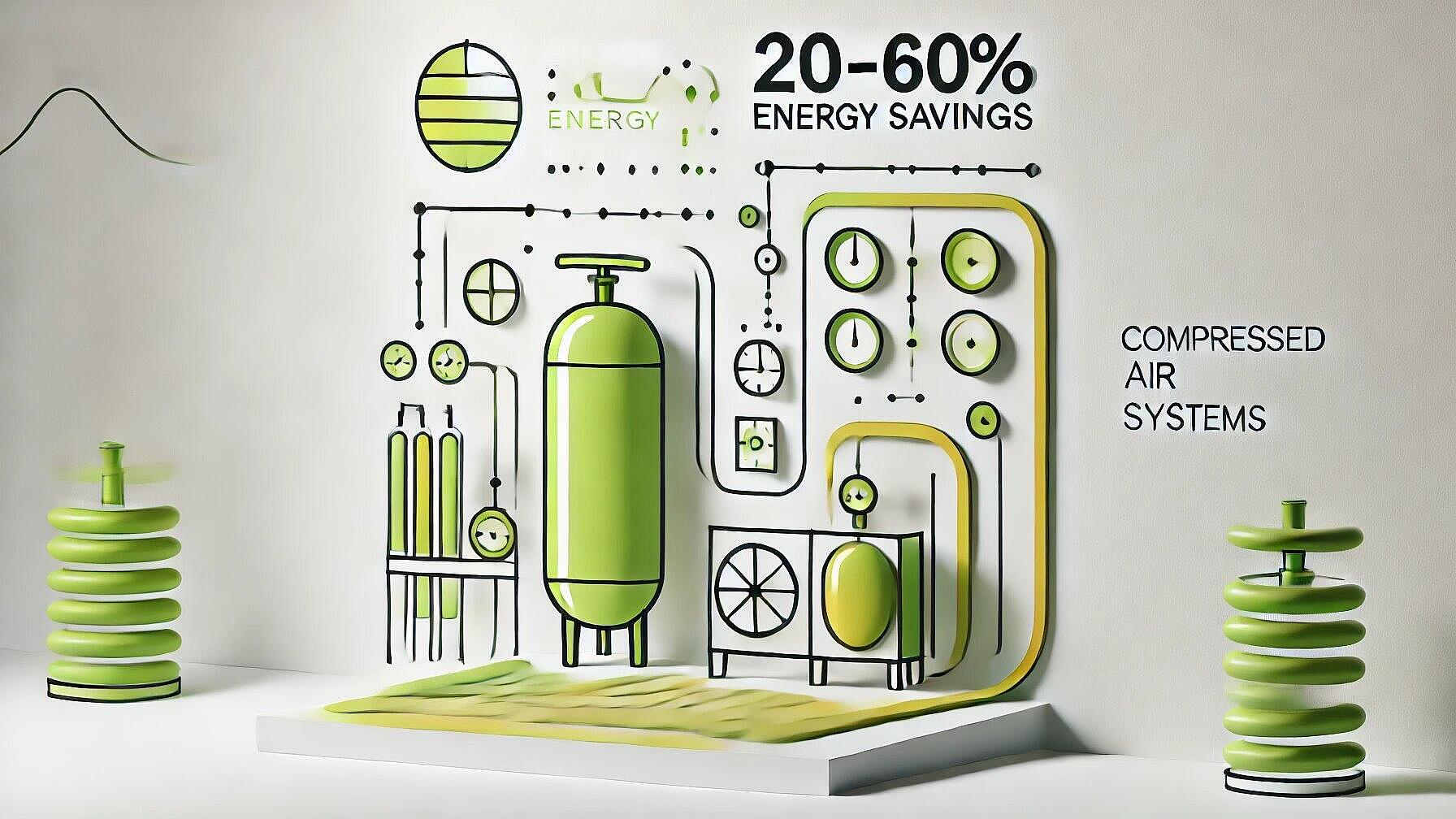

Read Full articlePowering Efficiency: Revolutionising Compressed Air Systems for a Sustainable Future

This study examines energy savings achievable in industrial compressed air systems (CAS). It highlights common inefficiencies such as leaks, improper storage, and suboptimal compressor location. Implementing best practices can reduce energy usage by 20-60%, implying substantial cost and environmental benefits.

Read Full articleRevolutionizing Pump Systems: The Power of Life Cycle Cost Analysis

Pumping systems represent significant energy and cost usage in industrial operations. Implementing thorough Life Cycle Cost (LCC) analysis can yield major savings by encompassing all ownership costs from initial purchase to decommissioning. Proper design, avoiding oversizing, and maintenance are crucial strategies.

Read Full articleDigital Solutions for Energy Efficiency in Industry

The 4E TCP report demonstrates how digital solutions in industrial motor systems enhance energy efficiency, with case studies showing benefits like reduced electricity consumption, improved operational flexibility, and lower maintenance costs. Advanced control systems, real-time data monitoring, and IoT technologies lead to significant energy and CO2 savings across various sectors, despite initial investment and implementation challenges.

Read Full articleDoubling Energy Efficiency Progress: A Key to Achieving Climate Goals and Energy Security

The IEA's Energy Efficiency 2023 report calls for doubling global efficiency efforts to 4% annually for achieving net zero targets, highlighting significant regional progress, job creation potential, and the necessity for a transformative industry shift, supported by robust policies and investment.

Read Full articleInnovative system recovers heat, water and material from industrial waste streams

The innovative Heat Pipe Condensing Economiser (HPCE) has been successfully commissioned at Alufluor AB in Sweden, demonstrating that significant heat, water, and material recovery is possible using current materials and knowledge. This milestone marks a major advancement in energy savings in the chemical process industry, showcasing the potential for substantial gains beyond incremental improvements. The project involved considerable engineering and infrastructure investment, leading to an operational capacity of 650kW from exhaust recovery since August 1st, and is applicable across various industries, particularly in regulated sectors.

Read Full articleEnergy Efficiency Or How SMEs Can Revolutionize Their Bottom Line

SMEs overlook 10-30% energy savings due to incomplete audits and complex consumption patterns. Adopting EMS offers cost reduction, improved productivity, regulatory compliance, and enhanced reputation. Barriers such as perceived costs, resource constraints, and lack of commitment hinder EMS implementation. Technology aids effective energy management, with smart meters and IoT enabling real-time data tracking. Best practices include starting with energy audits, setting reduction goals, and engaging employees. Successful EMS adoption in SMEs contributes to carbon emission reduction and energy transition goals, aligning with EU support for SME recovery and innovation.

Read Full article