Digitalisation

DigitalisationDigitalisation

Blockchain technology has yet to prove that it can meet the (very high) expectations. It is a distributed, digital peer-to-peer register, which stores every transaction between two connected agents in a ledger. To create sufficient security for a Bitcoin transaction block, it takes roughly 10 minutes to complete one transaction. In a 51% attack a single entity would have full control of the majority of the networks mining hash-rate and would be able to manipulate Blockchain. The Bitcoin API for developing services is difficult to use. A small chain that consists of a small number of nodes has a higher possibility of a potential of a 51 per cent attack. Another issue emerges when chains are split for administrative or versioning purposes. For the future, these costs could be cut by 80% with larger block size (4 MB per block, latency of 10 minutes. So at this point, we can conclude that the blockchain is a promising technology is very interesting.

Read Full articleCleantech startups: German utilities bridging the valley of death?

In the period from 2006-2008 clean tech was one of the hot topics for venture capital funds. At the MIT Gaddy et al (2016) compared the data from clean tech with two other technology sectors: Software and Medical. From this data we.

Read Full articleCan data analytics replace people in energy efficiency?

Data analytics can identify potential customers where there may be energy efficiency opportunities. Existing load information cannot determine exactly what is creating the load pattern. analytics can only provide directional vs. actionable information. It will never be able to gauge the interest .

Read Full articleCompressed Air: Energy efficiency at the top of the ComVac agenda (HM17)

The latest edition of ComVac will be staged from 24 to 28 April 2017 in Hannover, Germany. 260 exhibitors will be there in halls 26 and 27 to shocase the current state of the art in industrial compressed-air and vacuum-.

Read Full articleHydraulische Systeme - Optimierung Energieeffizienz

Kurzdarstellung des 4-Stufen Prozesses von KSB zur Optimierung der Energieeffizienz von hydraulischens Systemen. Mit einem Fokus auf den ges.

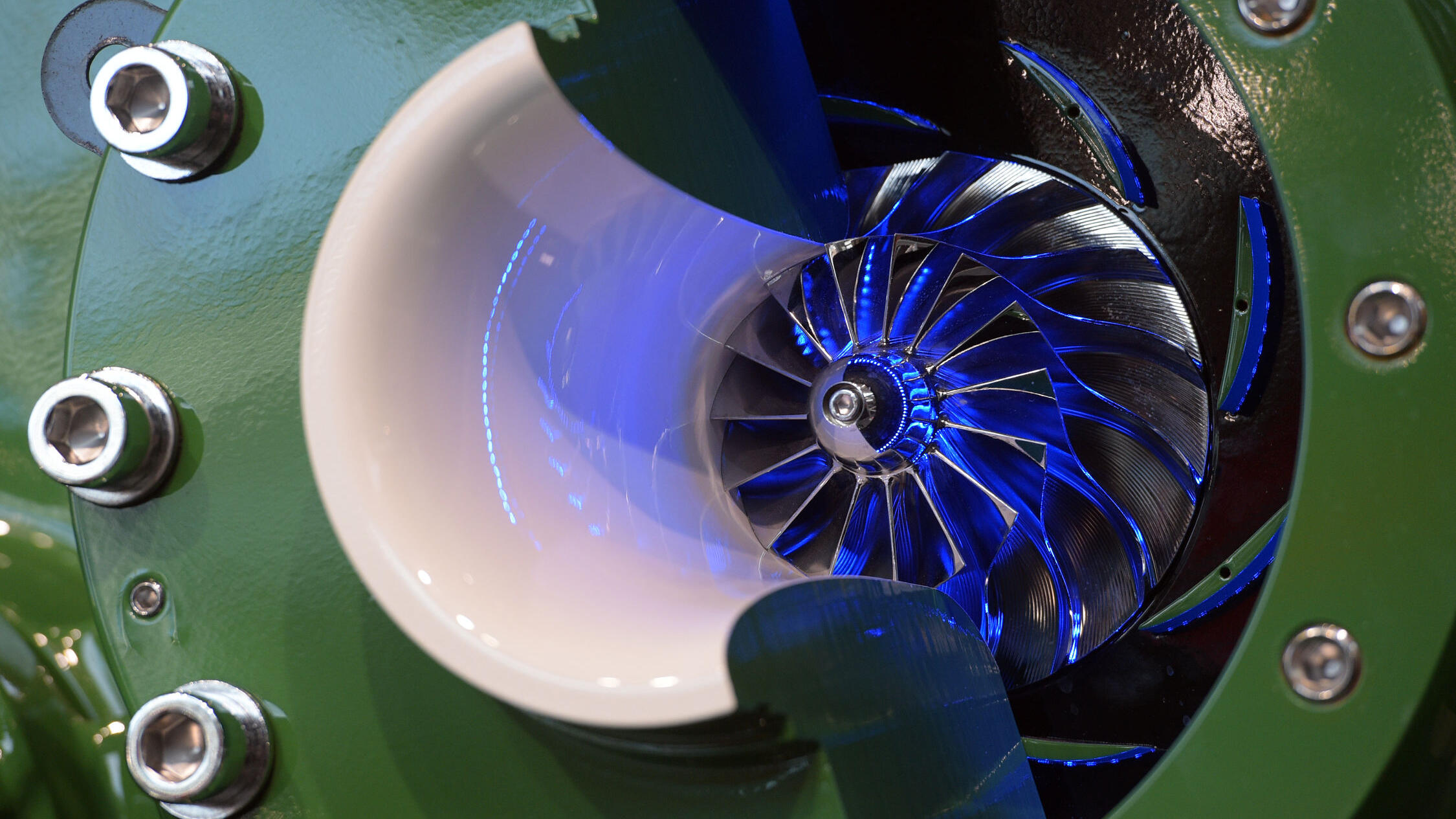

Read Full Business PracticeHydraulic system - energy efficiency optimization

This paper describes the 4 step approach of KSB to optimize the energy efficiency of a hydraulic system. It starts with a system analysis to detect optimization potential and ends with usage of smart pump technology and services during operation - see also paper on industry 4.0.

Read Full Business PracticeIndustrie 4.0 und smarte Pumpentechnologie

Smarte Pumpentechnologie und smarte Serviceleistungen kommen zusammen. Dies geschieht basierend auf den wesentlichen Produkteigenschaften Vernetzbarke.

Read Full Business PracticeIndustry 4.0 and smart pump technology

This paper shows the IoT or industry 4.0 approach of KSB. It describes how KSB sees smart pumps and smart services coming together. The paper also contains links to further information on KSB website. Back to Mail Online home.

Read Full Business PracticeNew - automated predictive maintenance using unstructured data

Warwick Analytics briefly describes their next level software developments leading to automated predictive maintenance. It also claims to solve implementation barriers like unstructured data or complex IT integration. The benefits of such tools like reduced downtime and a reduction of energy and waste is not new.

Read Full Business PracticeCybersecurity solutions designed to ensure the operational continuity of industrial (ICS/SCADA) networks

This short paper highlights the new risks that manufacturing companies are exposed to due to the adoption of IoT/Industrie4.0 technologies. SCADAfence at worlds leading trade fair Hannover Messe 2016, hall 7, stand A02.

Read Full Business Practice