Energy Efficiency

is connected

Energy Efficiency

is connected

The 2025 Energy Pivot: Navigating Europe's New Compliance Landscape for Business

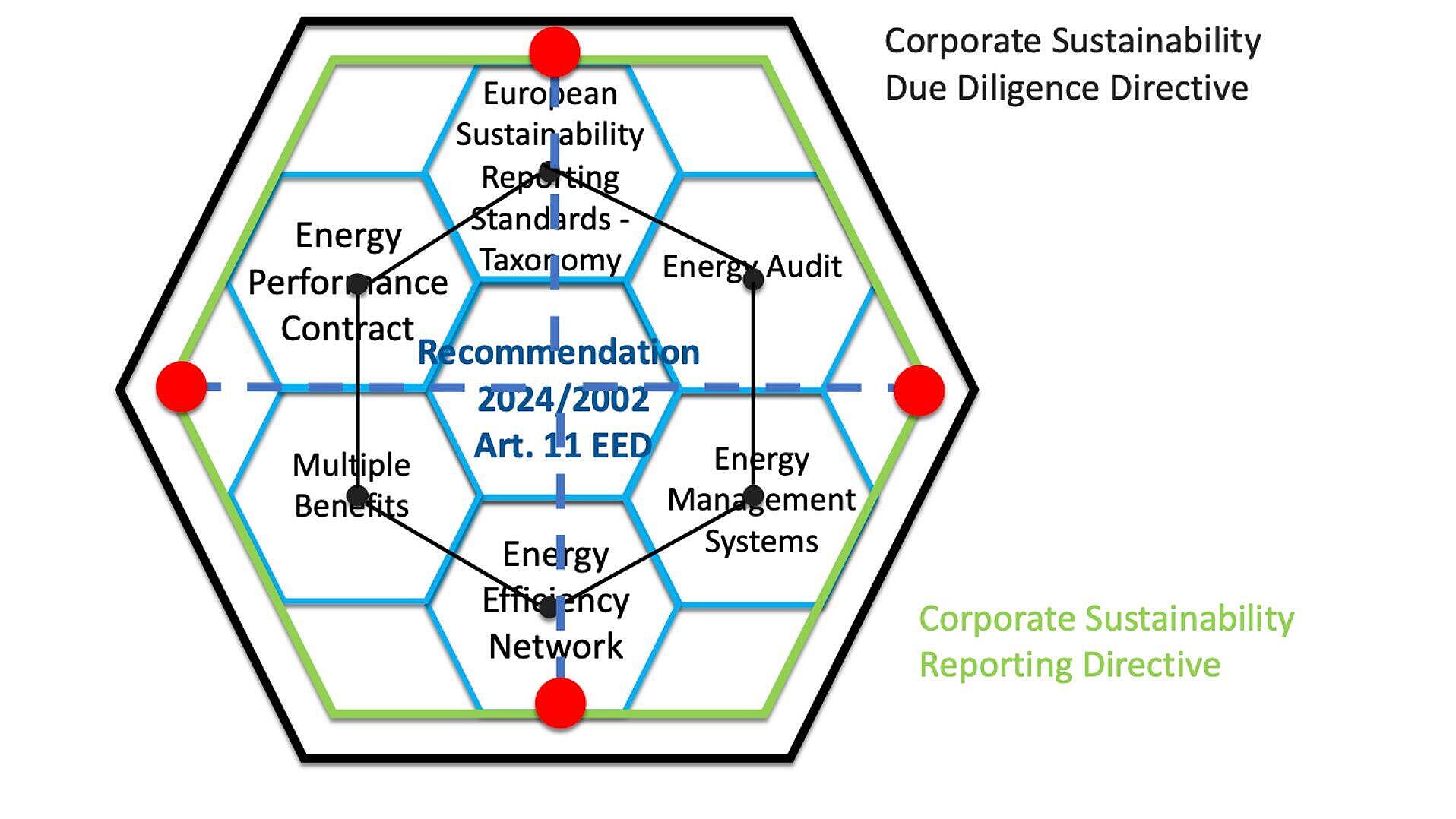

Europe’s energy policy shift culminates in 2025, when major EU directives move from negotiation into national laws that create concrete compliance duties for businesses. The recast Energy Efficiency Directive turns “Energy Efficiency First” into a legal requirement and replaces size-based obligations with energy-consumption thresholds: firms above 10 TJ must conduct energy audits, and those above 85 TJ must implement energy management systems. In parallel, RED III raises the 2030 renewables target to 42.5% (aspiring to 45%) and tackles the biggest practical barrier—permitting—by introducing renewables acceleration areas with time-capped approvals and treating renewable projects as overriding public interest. Industry also faces binding requirements to increase renewable energy use by 1.6% annually, including uptake of RFNBOs such as green hydrogen. Looking beyond 2025, attention shifts to grid constraints and tougher 2040 climate targets.

Leer Artigo completoEstá a ser dado mais apoio às PME na Europa para se tornarem mais eficientes do ponto de vista energético

O Grupo do Banco Europeu de Investimento, com o apoio da Comissão Europeia, concederá 17,5 mil milhões de euros de financiamento a mais de 350 000 PME europeias para melhorar a eficiência energética, quase duplicando a ajuda atual, com vista a um investimento total de mais de 65 mil milhões de euros até 2027.

Leer Artigo completoA corrida sem precedentes: como a IA está a remodelar os nossos mundos digital e físico

Até 2030, a IA necessitará de um investimento de 7 biliões de dólares em centros de dados, impulsionado pela adoção generalizada da IA e pelas prioridades geopolíticas. A demanda por hardware de computação especializado e cargas de trabalho de IA com uso intensivo de energia está criando desafios significativos de energia e cadeia de suprimentos, enfatizando a necessidade de eficiência, energia renovável e previsão avançada de demanda.

Leer Artigo completoDestaque para o projeto financiado pela UE - Libertar o potencial das PME: Financiar a eficiência energética para um futuro sustentável

O documento sublinha a importância da eficiência energética nas PME europeias, que são cruciais para a economia e competitividade do continente. O projeto DEESME 2050, financiado pela UE, destaca os potenciais benefícios da melhoria do desempenho energético na indústria do mobiliário. Os investimentos e a implementação de políticas devem ser acelerados para cumprir os objectivos climáticos da UE para 2030, e novas iniciativas como a EEEFC visam apoiar esta transição. Os intermediários financeiros são identificados como vitais para o acesso das PME aos fundos, aproveitando as experiências de organizações como a EEIP e os bancos públicos para facilitar este processo.

Leer Artigo completo⚙ Práticas comerciais

Os sistemas de ORC estão a ajudar a criar um futuro energético sustentável

A tecnologia do Ciclo Rankine Orgânico (ORC) está sendo usada na Suécia para transformar o calor residual em eletricidade renovável. A forma de alta eficiência e baixa manutenção para produzir electricidade sustentável está a ser adoptada pelos sistemas de aquecimento urbano em todo o mundo. Leia como Ronneby.

Ler maisTecnologia de Ciclo de Rankine Orgânico com aplicações em solução de Recuperação de Calor

ORC RANK tem trabalhado com SWEP para implementar uma solução de recuperação de calor para geração de energia elétrica. A faixa de ativação para os equipamentos de baixa temperatura começa em apenas 85 °C. Os permutadores de calor SWEPs são instalados como economizadores.

Ler mais⚙ Tecnologia de Eficiência Energética

Desbloquear o verdadeiro valor: Porque é que os benefícios múltiplos são o futuro da eficiência energética

⚙ Serviços de Eficiência Energética

⚙ Recuperação de Energia e DHC